Z-Axis Test Fixture Kits

-

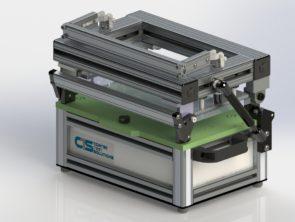

Z-Axis Test Fixture Kit 1208 Test Area up to 10.0” x 6.0”

From $2,000.00

Select Options

Z-Axis Test Fixture Kit 1208 Test Area up to 10.0” x 6.0”

From $2,000.00

Select Options

-

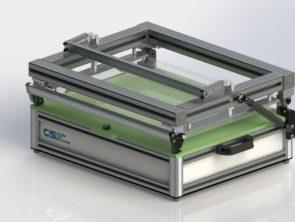

Z-Axis Test Fixture Kit 1612 Test Area up to 14" x 10"

From $2,300.00

Select Options

Z-Axis Test Fixture Kit 1612 Test Area up to 14" x 10"

From $2,300.00

Select Options

-

Z-Axis Test Fixture Kit 2016 Test Area up to 18.0" x 14.0"

From $2,650.00

Select Options

Z-Axis Test Fixture Kit 2016 Test Area up to 18.0" x 14.0"

From $2,650.00

Select Options

Cortek’s Z-axis test fixture kits provide a low cost solution for testing printed circuit boards with true linear engagement when a traditional "clamshell" style test fixture is unacceptable. Z-Axis vs. Clamshell Comparison. The Z-Axis Assembly replaces the hinged top push plate that is standard on our kits. Available in our standard sizes and as an individual assembly for field upgrade for our test fixture kits should it be determined later that it would be beneficial. Like our standard mechanical fixture kits, these units are adaptable should you require a custom size. Purchase the Individual Assembly Click here to see our Test Fixture Gallery

Key Features

- Unobstructed working area within the push plate. No cross bars to deal with which allows complete access to the top side of the UUT.

- A full ¾” of travel in the Z axis.

- Easily replaceable top plate. The personalized top plate can be removed via four screws. ECO’s or new product types will not make the Z axis assembly obsolete.

- The actuation design multiplies the force input from the operator. Much higher force can be applied to the UUT without fatiguing your operator. This allows for higher probe counts without sacrificing probe spring rates.

- Accurate and repeatable actuation. Top and bottom probing and/or fine pitch probing can be done without side loading of the probes.

- Robust design with four linear guides. Suitable for lab or harsh environments.

- Gas spring supports balance the effort of opening and closing the fixture.

Options:

- Customization of fixture plates – submission of data required for quote

- FR4, Acrylic, Polycarbonate ESD plates available

- Installation of fixture hardware to include: Probes & Sockets, locating pins, push rods, side guides, connectors, interface pcb, interlocks, etc.

- Wiring per customer specification

- Safety shroud

- Stripper plate