Z-Axis vs “Clamshell” Test Fixture Kits

“Clamshell” or Standard Mechanical Test Fixture Kit

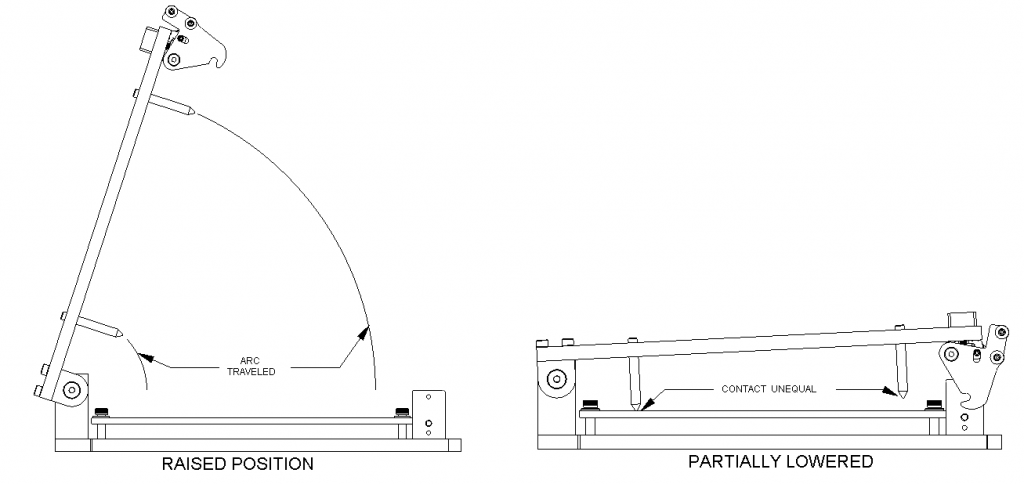

Below is a side view of a standard “clamshell” fixture hinged top plate mechanism. (Click image to enlarge)

In the left figure you see the arc that the UUT contact points will follow as the fixture is closed and actuated. To the right you see how the rear contact area follows a smaller arc and will make contact long before the right hand contact point. This causes a side loading of all contact points. The UUT will be pushed towards the opposite edge, away from the pivot point. This system can be perfectly fine for many UUT types and fixture layouts.

For certain applications this type of actuation is unacceptable. Spring loaded probes that are side loaded tend to have shorter life spans and intermittent contact problems. Dual access (probing from opposing directions) can be very unreliable if not impossible.

High test pin counts typically have higher forces that need to be applied to the UUT. High probe pressures become problematic for the operator to actuate the fixture. Reducing probe spring pressure to compensate for higher force can cause the probes to make poor electrical contact.

Z-Axis Test Fixture Kit

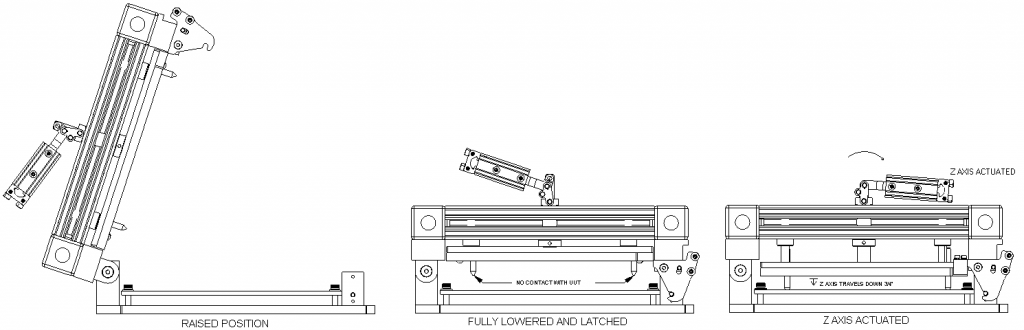

In figure 2 you see the three positions of the Z axis. In the raised position, left, you have the same accessibility to the UUT area as a standard system. The UUT contact points will follow the same arc shown in figure 1 but when closed, center, the contact points do not touch the UUT. Only after actuating the Z axis do the contact points push against the UUT. The linear movement in the Z axis eliminates the sideways pressure on the UUT and probes. The linear Z movement provides consistent controlled contact to the UUT which can dramatically improve the life cycle of the probes.

The linear movement also opens up other opportunities during the probing of a UUT.

• Probing next to tall components that could shadow accessibility to a test point.

• Probing fine pitch locations with small and delicate probes that cannot tolerate side loading.

• Utilizing the Z axis movement to operate other probing mechanisms like side access of a connector. Essentially allowing probing in the X, Y and Z axis.