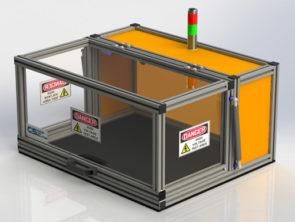

Safety Enclosure - Personal Protective Equipment

Cortek Test Solutions DUT HiPot Safety Enclosures, also known as “Personal Protective Equipment” (PPE) are designed to prevent the potential of electrical shock when used properly while conducting electrical safety testing of products. Our HiPot test equipment comes standard with a magnetic safety interlock switch and chassis ground connection that must be wired from the safety enclosure to the HiPot tester or any earth ground connection by the customer for safe operation. A key differentiator of our products is that they are easily scaled in the X, Y and Z axis to accommodate the product’s required testable area within the enclosure. If the size of our standard off-the-shelf units do not work for your application, you can request a quote for a custom size.

The hazards of electrical shock range in severity from tingling sensations to a potentially lethal jolt. Therefore, identifying and eliminating shock hazards is incredibly important when performing electrical safety testing. Various types of product testing include: high voltage test (Dielectric test), insulation resistance test, earth ground continuity test, and leakage current test (Line Leakage) to ensure safety to the end user and to conform to product safety agency standards.

Are you risking the company staff to unnecessary High Voltage discharge with ineffective safety controls? Cortek Test Solutions wants to assist in protecting your greatest assets with our off-the-self or custom CTS High Voltage Safety Enclosure used in High Voltage testing. CTS High Voltage Safety Enclosures are a Personal Protective Equipment or “PPE” designed to provide a safe environment for Hi-Pot testing devices. The Enclosure reduces the hazard of High Voltage discharge and safeguards operators from the dangers associated with High Potential Testing. Cortek Test Solutions High Voltage safety enclosures are built with your safety needs in mind. When used properly, CTS safety enclosures can prevent injury from high voltage electric discharge and damage to devices being tested. The enclosure comes equipped with a magnetic safety interlock switch and chassis ground connection that must be wired from the safety tester to the safety enclosure for safe operation. See below for key features and options.

Key Features:

- Aluminum frame construction to be grounded by customer to prevent electric shock

- Acrylic cover

- Safety magnetic interlock switch

- Chassis ground wire connection to be hooked up by customer

- Safety yellow panels

- Terminal block with 20 positions and removable cover

- D-Sub 9 pin connector

- Flexible Grommet 2” for pass through cables

- [3] High Voltage Test Area stickers

Options:

- Light Tree

- Easily Scalable

- Polycarbonate available

- Custom options available