Mechanical Press Fixture Kits

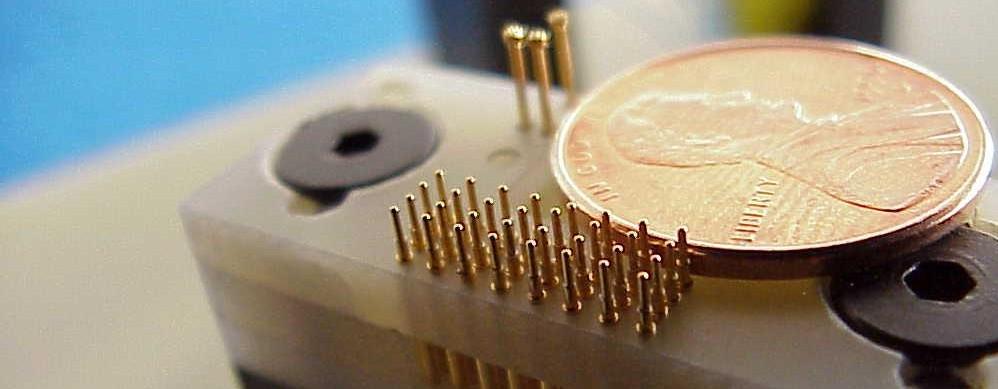

For more than 20 years, Cortek Test Solutions has manufactured our premiere off-the-shelf Mechanical Press Fixture Kits in two standard sizes. Our Mechanical Presses offer the versatility to change out fixture plates which enables our customers to test multiple products on the same fixture kit. This flexibility makes it a cost-effective testing solution that also standardizes your test setup. Our Press Fixture Kits are designed to provide precise, bed-of-nails contact in both R & D and production environments.

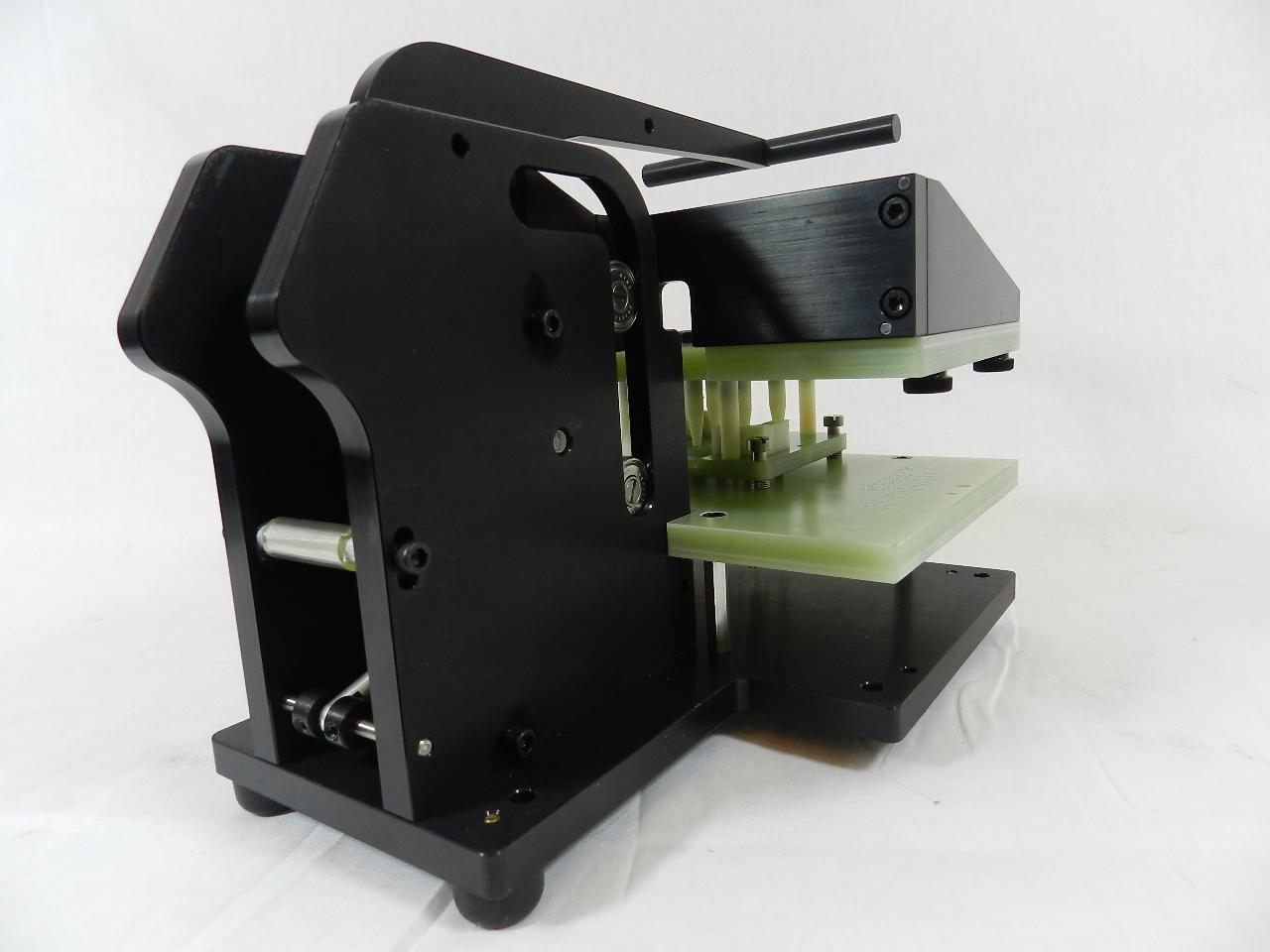

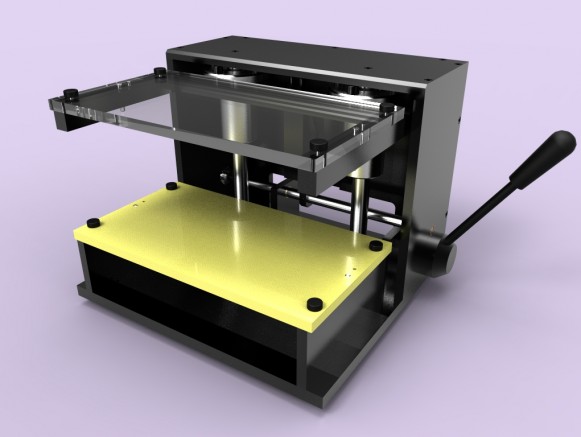

Mechanical Press Fixture Kit #9560

The 9560 Mechanical Press is a reusable fixture kit that can be customized with different fixture plates for flexibility to test multiple products. Durable aluminum and steel construction, precision bearings and hardened steel Thompson rods ensure accuracy and repeatability to contact test points on centers as close as 20 mils.

- Test Area: 9.5” x 6.0” (UUT may extend beyond test area)

- Maximum Load: Standard up to 100 lbs.

- Dimensions: (W x H x D): 12” x 9.25” x 11.5”

- Weight: Approximately 35 lbs.

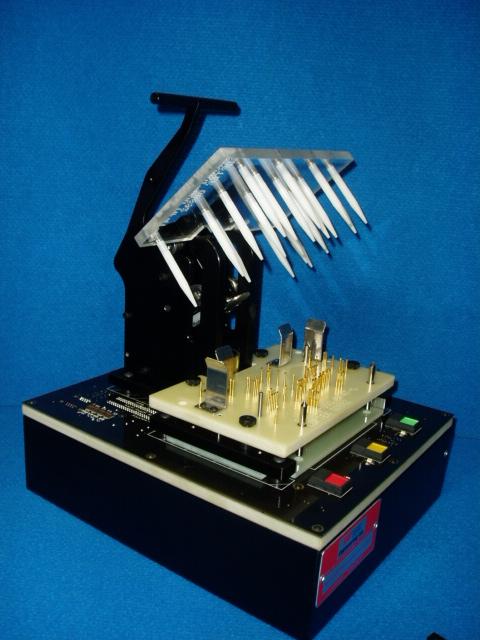

Mechanical Press Fixture Kit #1012

Like the 9560, the 1012 Mechanical Press is a reusable fixture that can be outfitted with different fixture plates to allow for testing of multiple products. Durable aluminum and steel construction, precision bearings and hardened steel Thompson rods ensure accuracy and repeatability to contact test points on centers as close as 20 mils.

- Test Area: 10” X 12” (UUT may extend beyond test area)

- Maximum Load: Standard up to 100 lbs.

- Dimensions: (W X H X D): 15.5” x 10” x 16”

- Weight: Approximately 50 lbs.

About Mechanical Press Fixture Kits

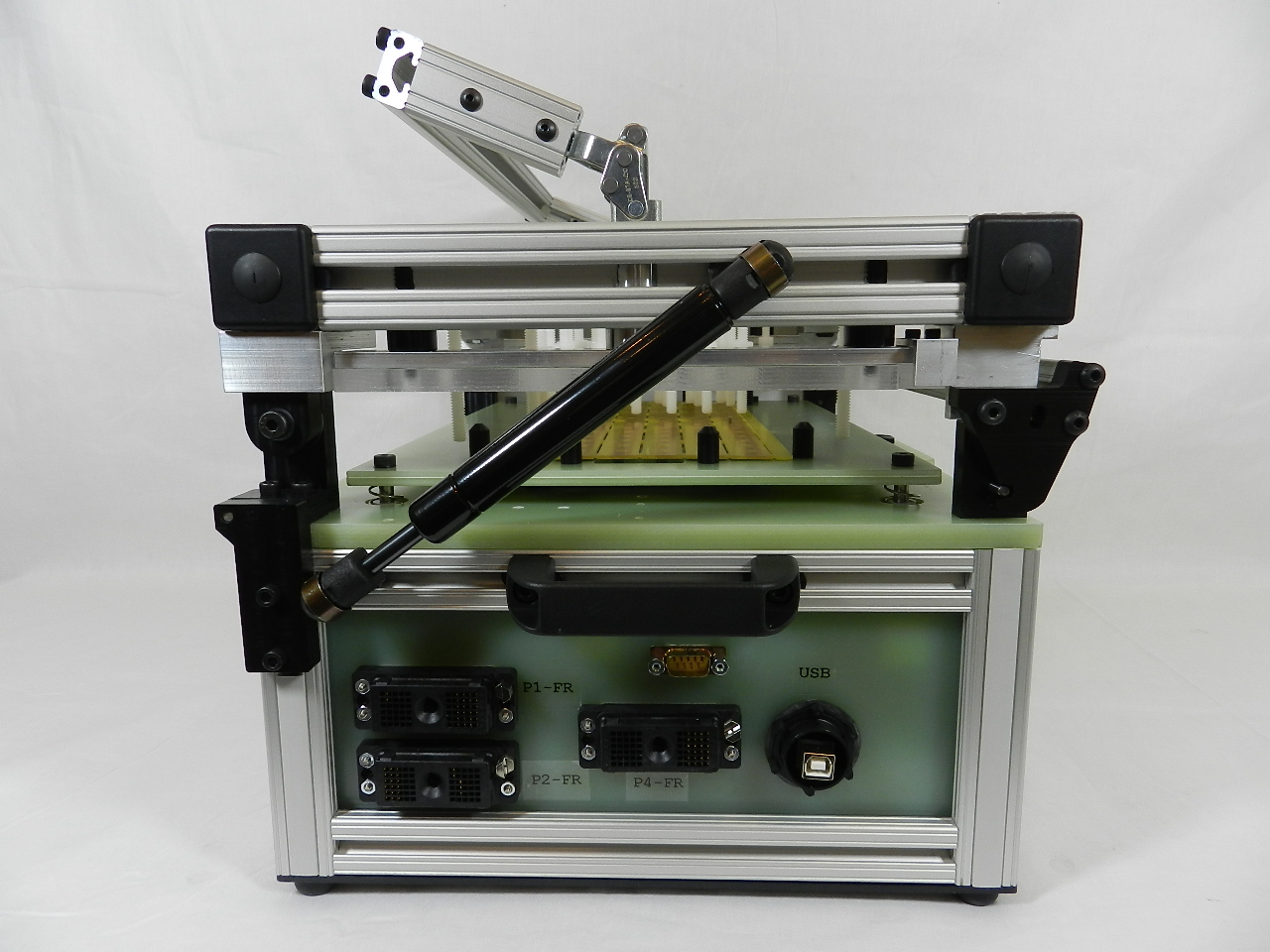

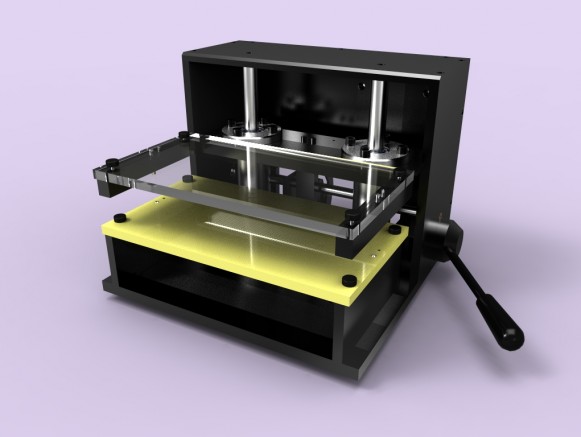

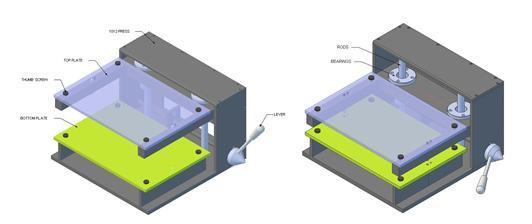

The mechanical press is a lever actuated vertical clamping press.

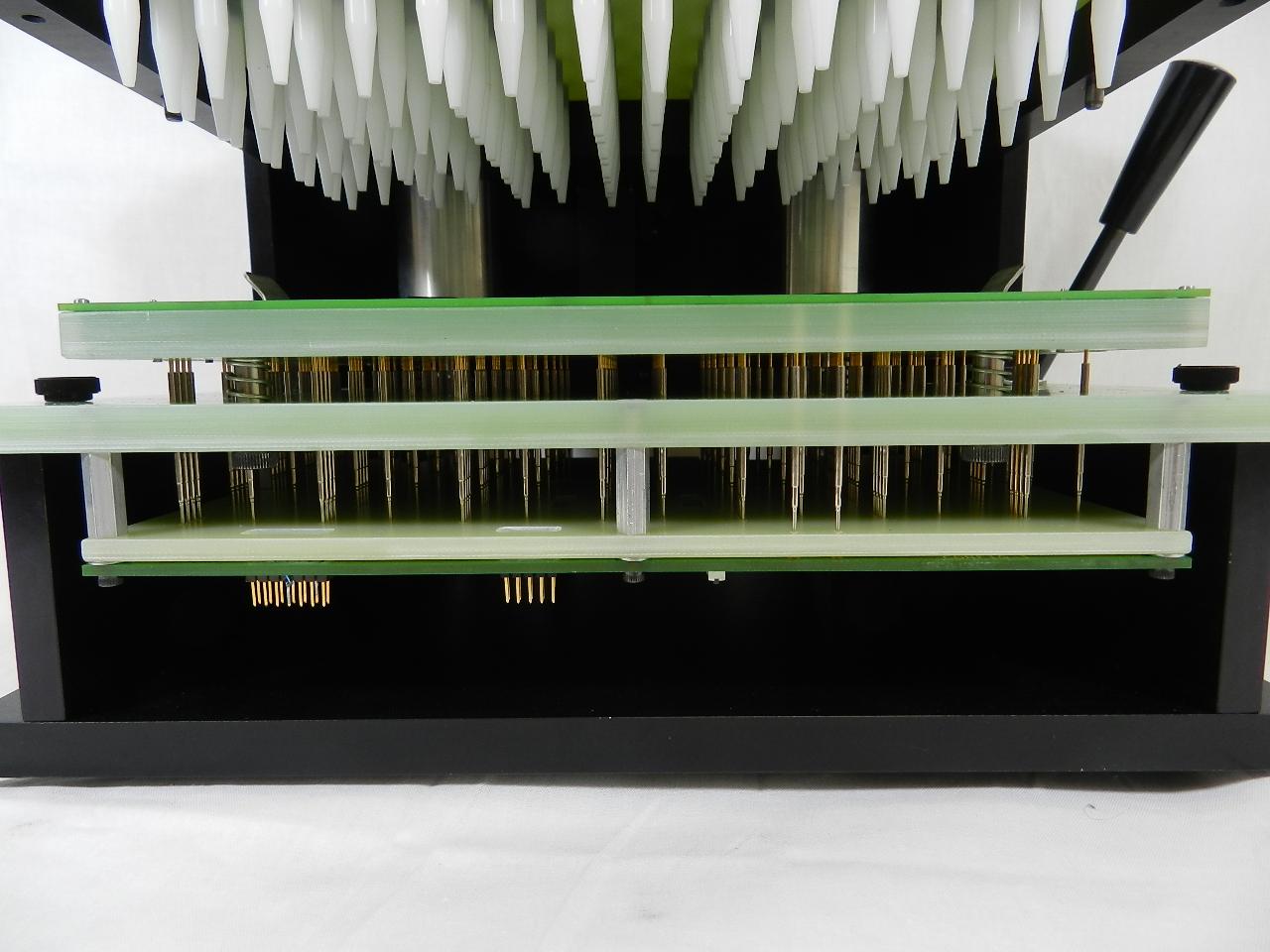

When the lever is moved the top plate is lowered through a geared toggle clamp mechanism that multiplies the force being exerted by the operator so that large forces can be applied by the clamping mechanism without operator fatigue. The upper mechanism travels on precision rods and bearings that insure precise repeatability with each actuation and a long service life.

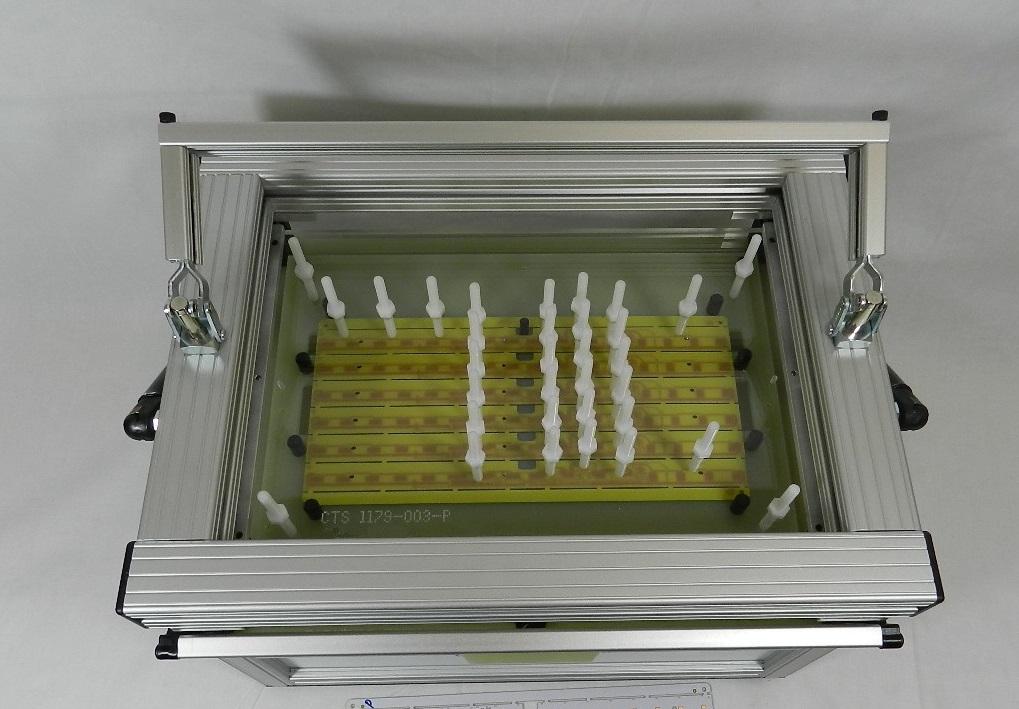

Fixtures can be removed from the press without tools by unscrewing the four thumb screws that hold down the top plate and the four thumb screws that hold the lower plate.

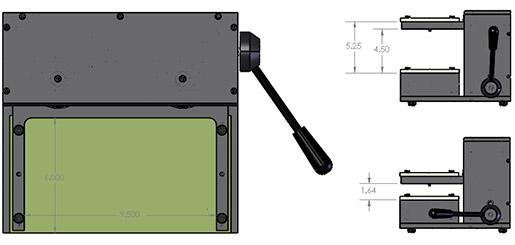

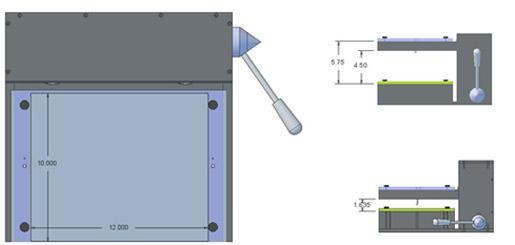

Press Clearance Dimensions

Mechanical Press Fixture Kit #9560

The working area of the fixture plates that is unobstructed by the press mechanism is 6″ in depth by 9.5″ in length. In the raised position the working area between the moving clamp plates top surface is 5.25″ and the lower side is 4.50″. The top plate is shown mounted to the top of the moving mechanism where there is maximum clearance for the UUT but it can also be mounted to the underside if desired. When actuated the clearance between the upper and lower clamp mounting points is 1.635″.

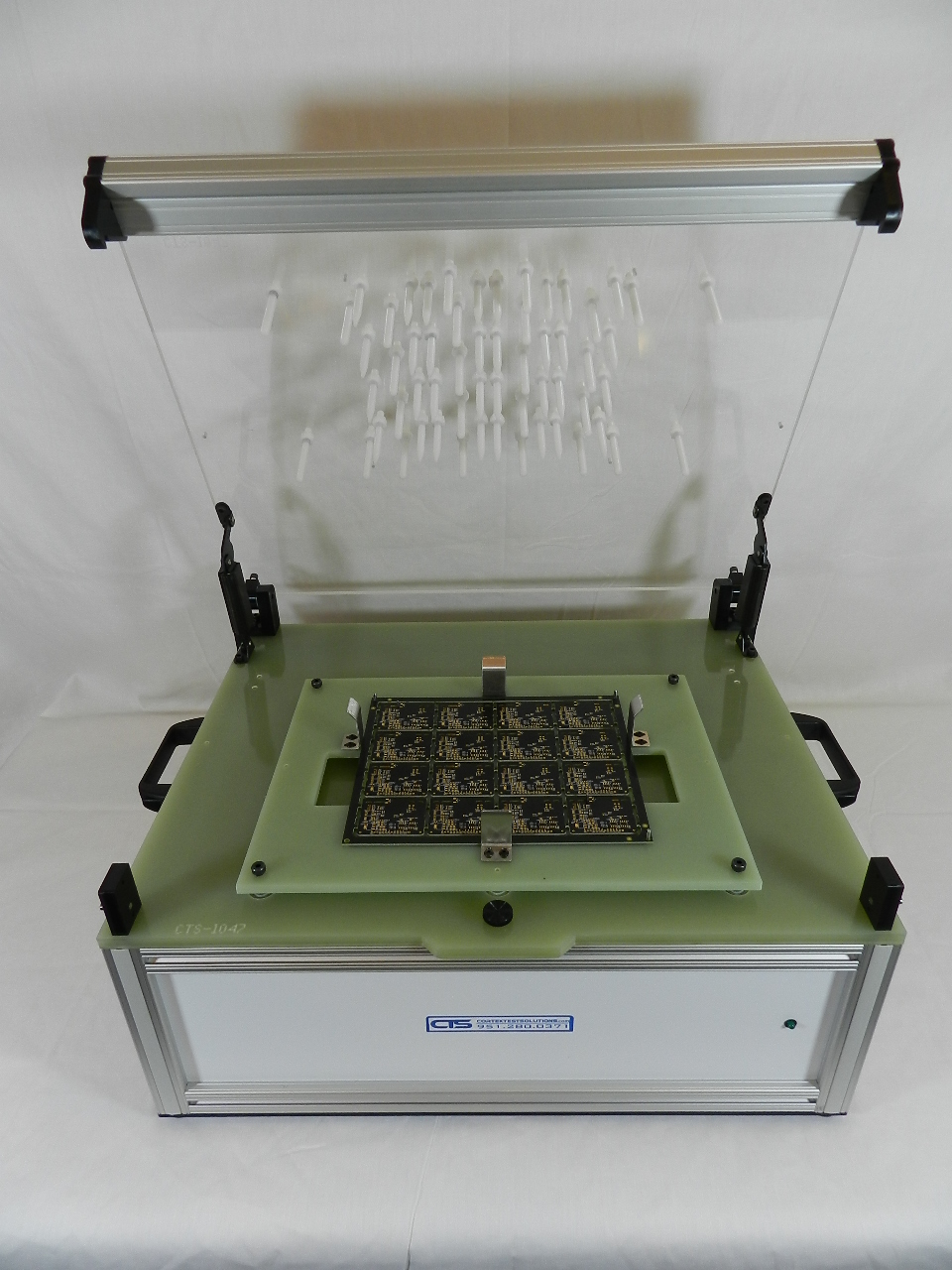

Mechanical Press Fixture Kit #1012

The working area of the fixture plates that is unobstructed by the press mechanism is 10″ in depth by 12″ in length. In the raised position the working area between the moving clamp plates top surface is 5.75″ and the lower side is 4.50″. The top plate is shown mounted to the top of the moving mechanism where there is maximum clearance for the UUT but it can also be mounted to the underside if desired. When actuated the clearance between the upper and lower clamp mounting points is 1.635″.

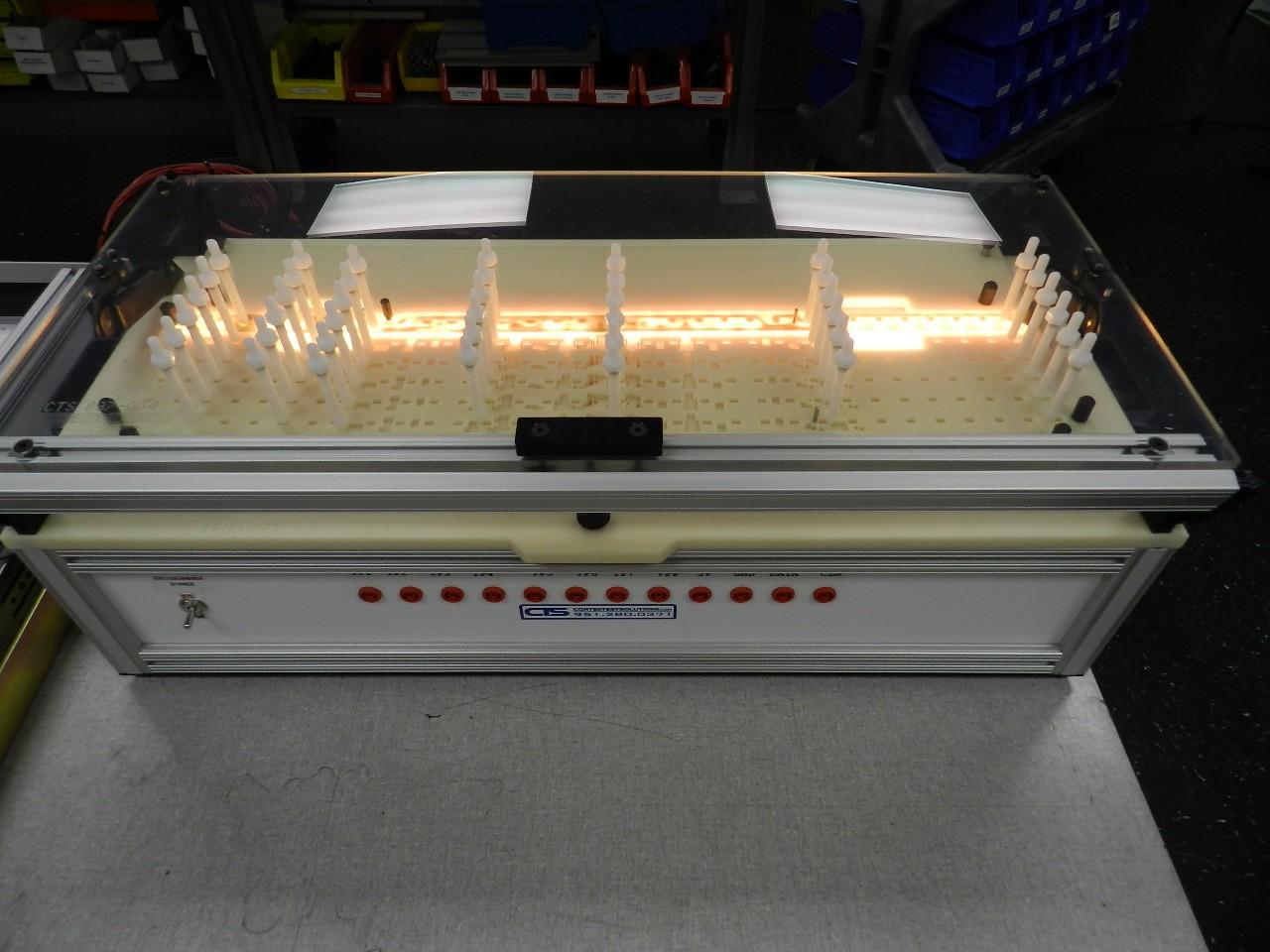

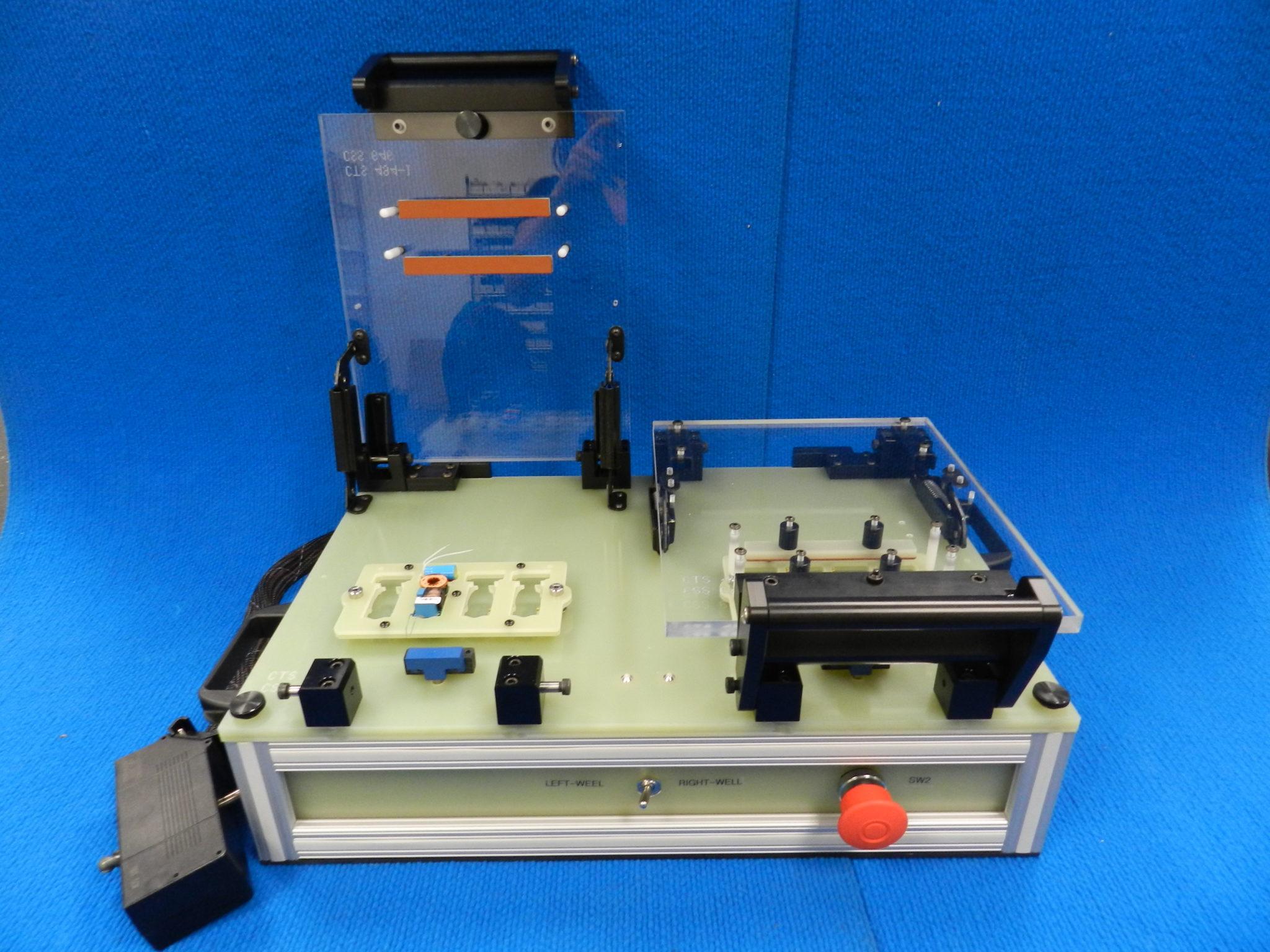

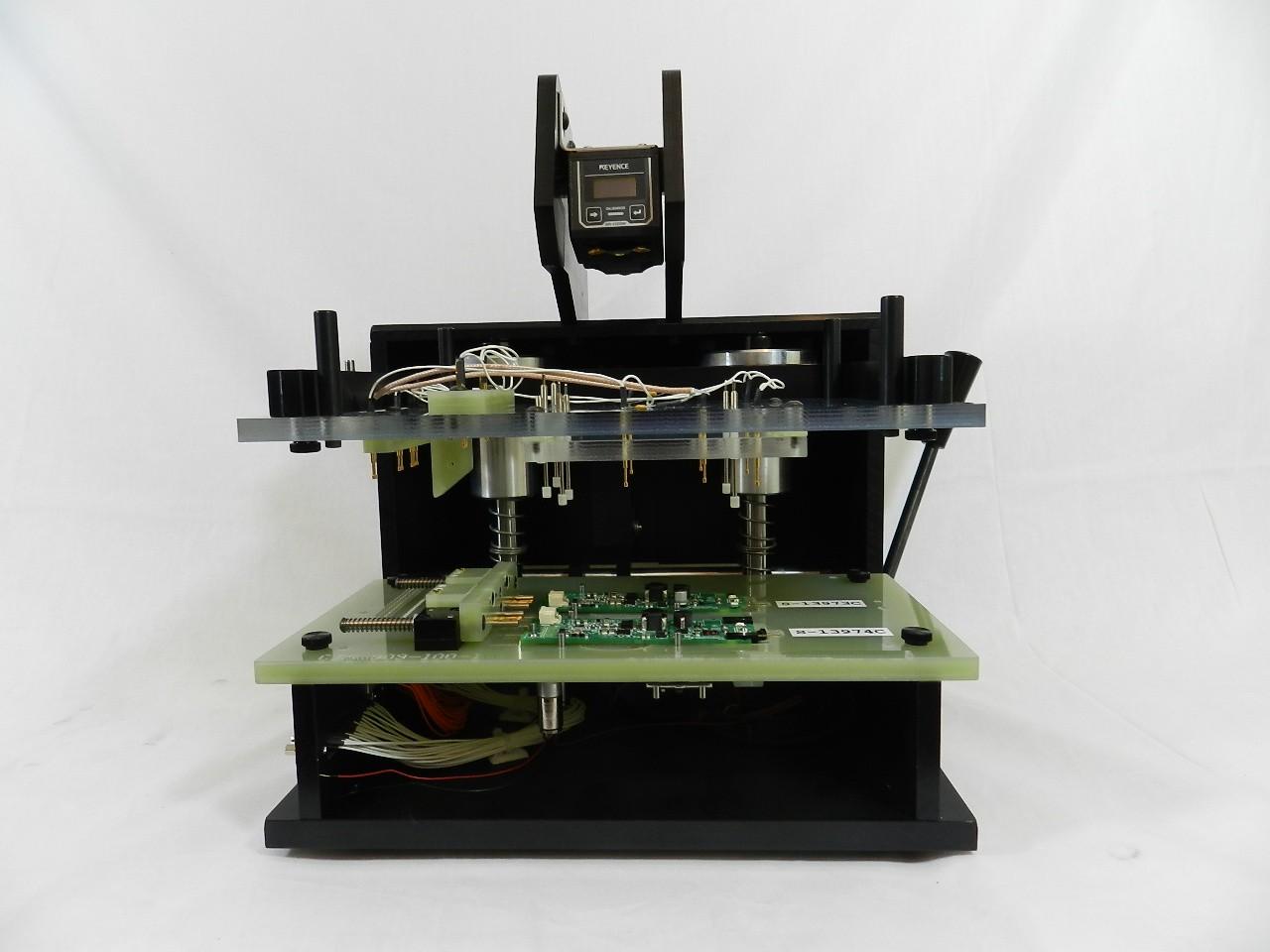

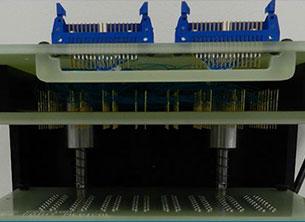

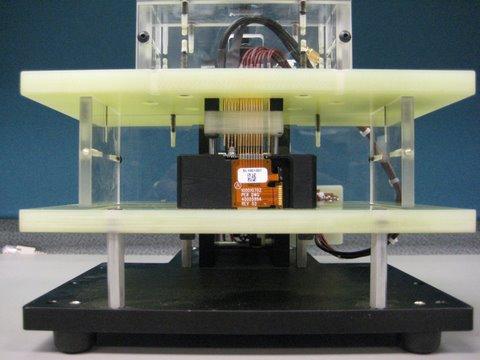

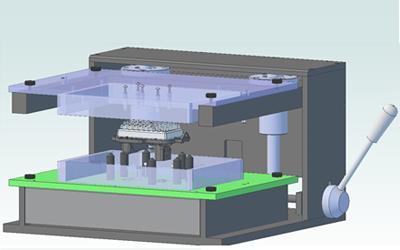

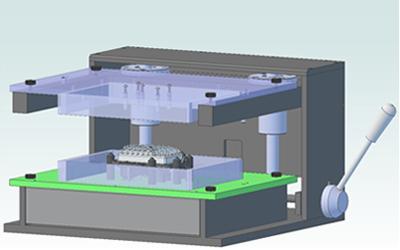

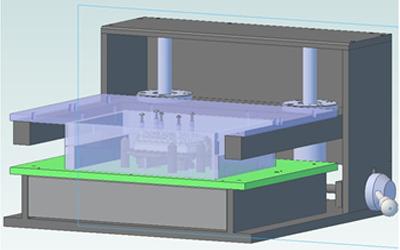

The following pictures show the press with personalized top and bottom fixture plates:

Open with device placed in fixture

Device lowered into test position

Press actuated bringing device into contact with test pins and preventing the operating from touching the device during the test cycle

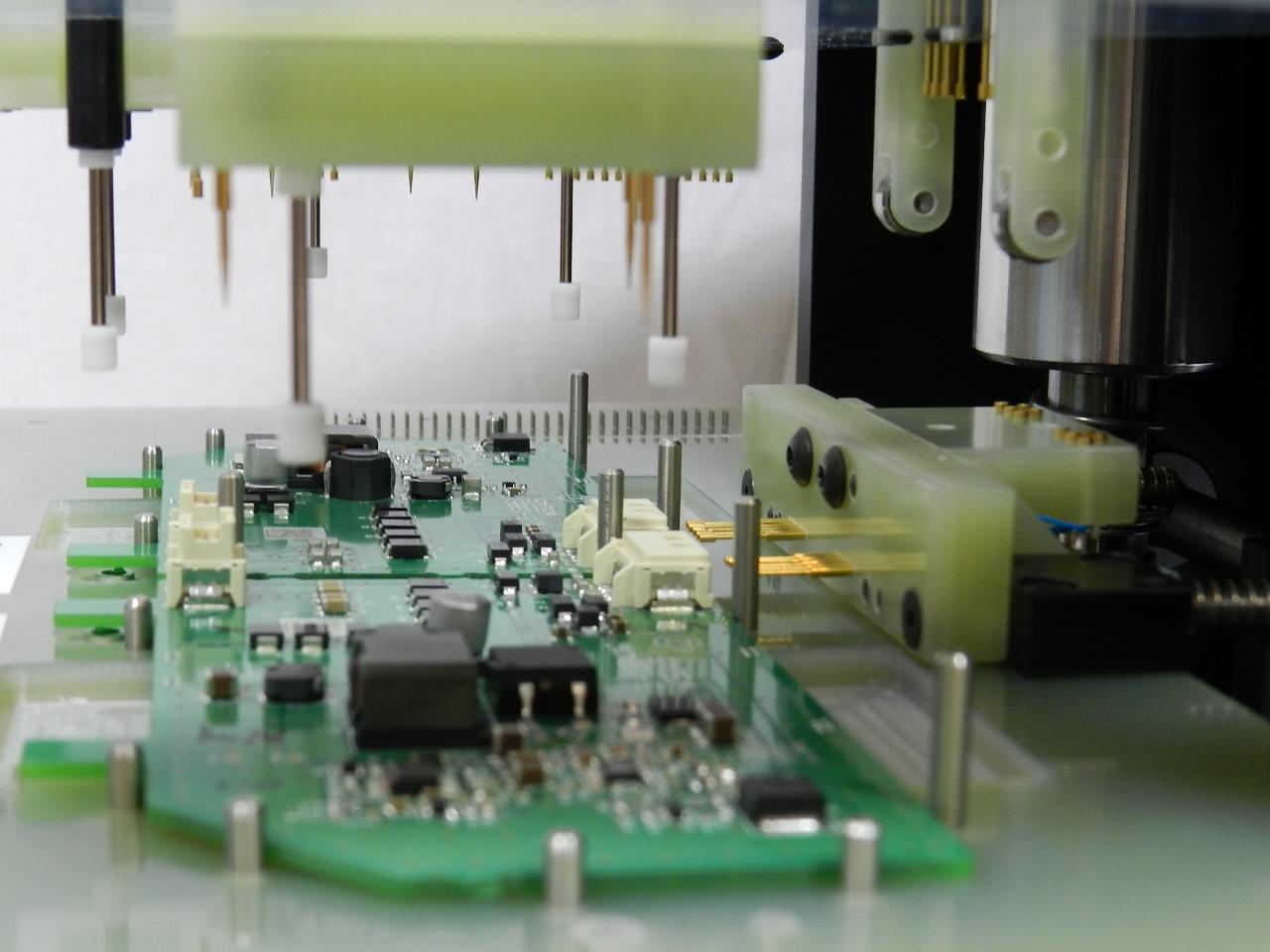

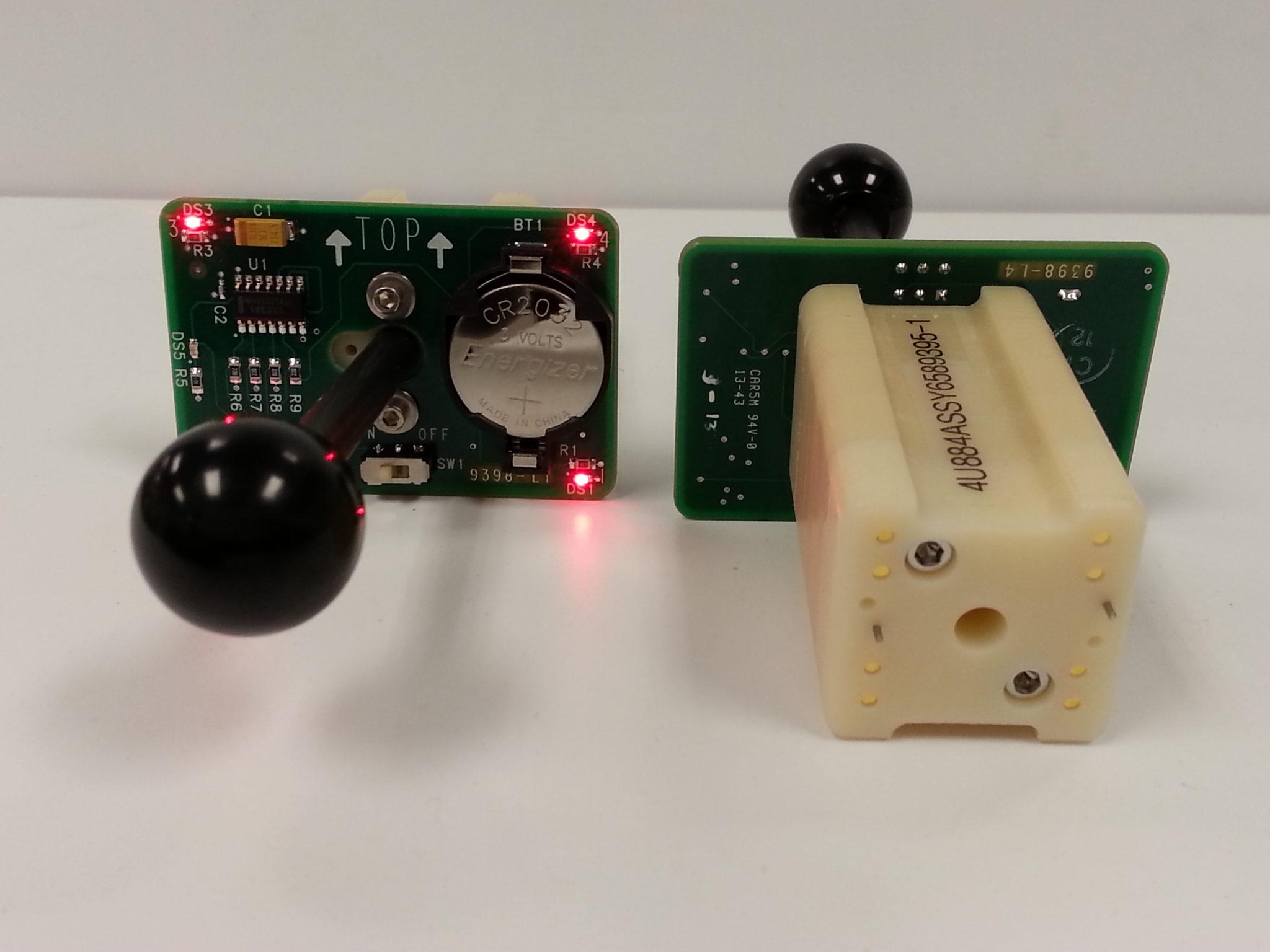

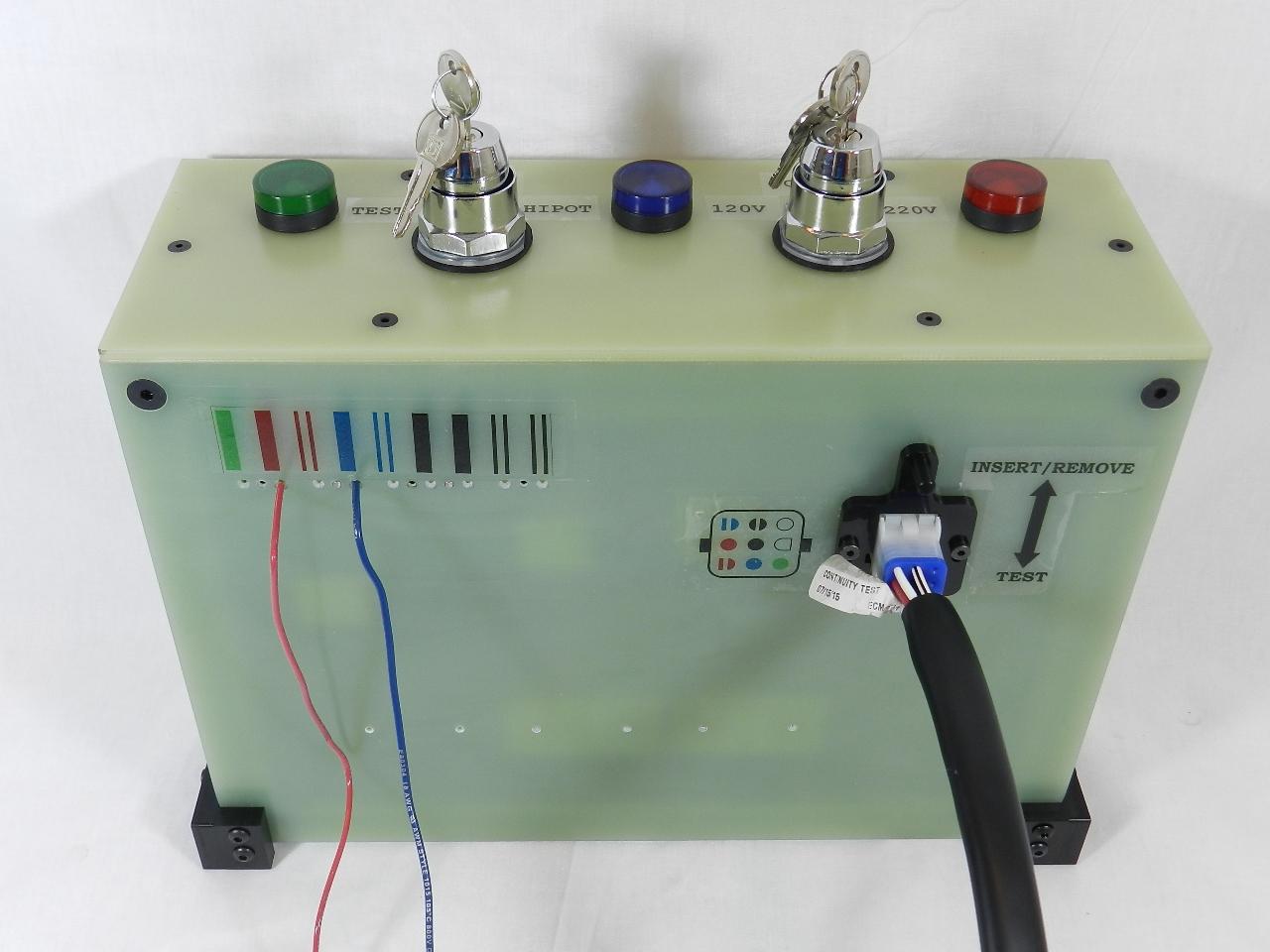

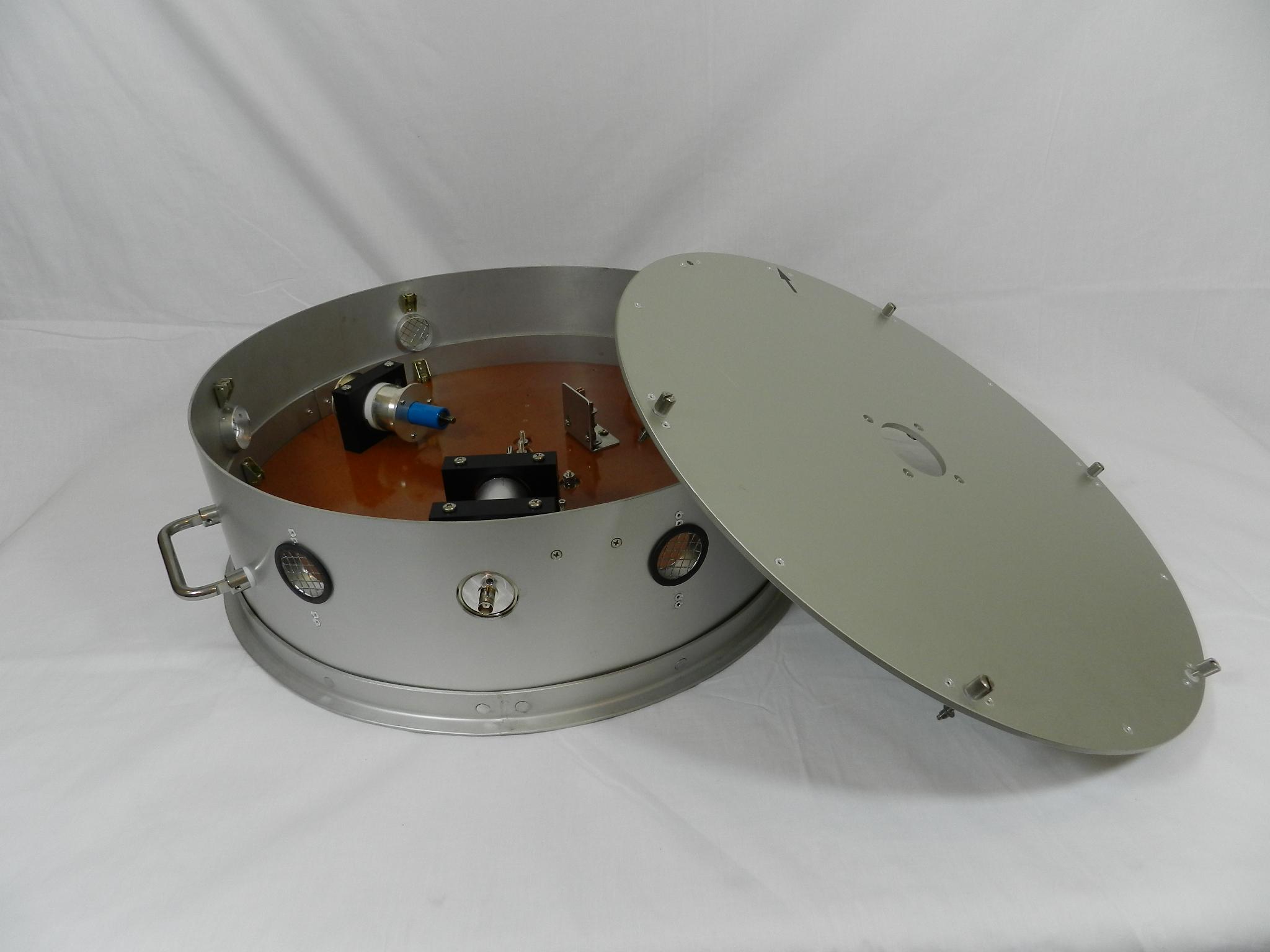

Custom Test Fixtures

Cortek specializes in creating custom solutions for test fixture units that require functional testing. Our team designs and manufactures a machine to test each of our customers needed requirements. Our functional test kits offer flexibility and robust features and come in a variety of sizes. From simple mechanical test fixtures, to intricate functional test units that interface with test software, CTS will provide the solution needed to get the job done.