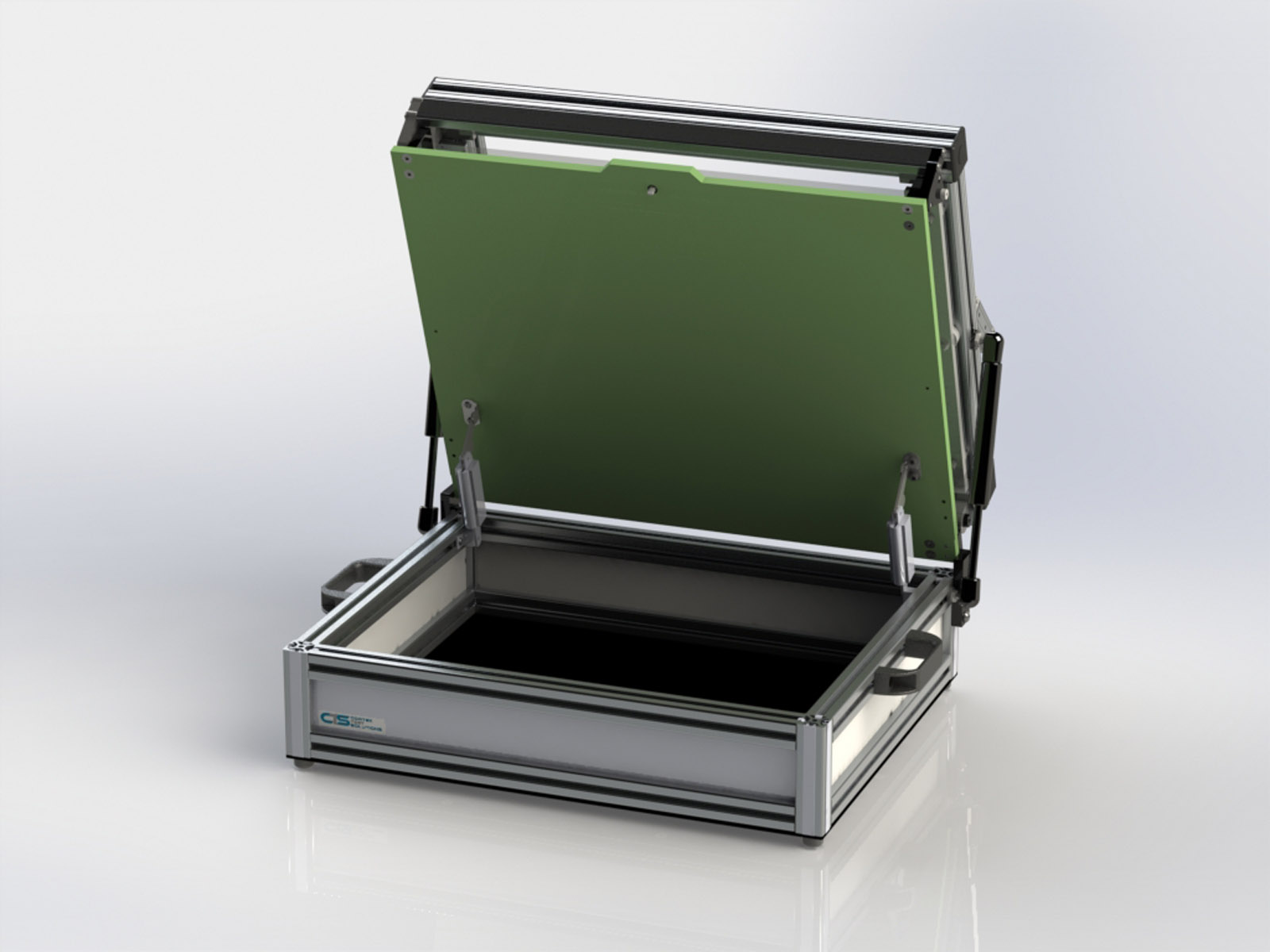

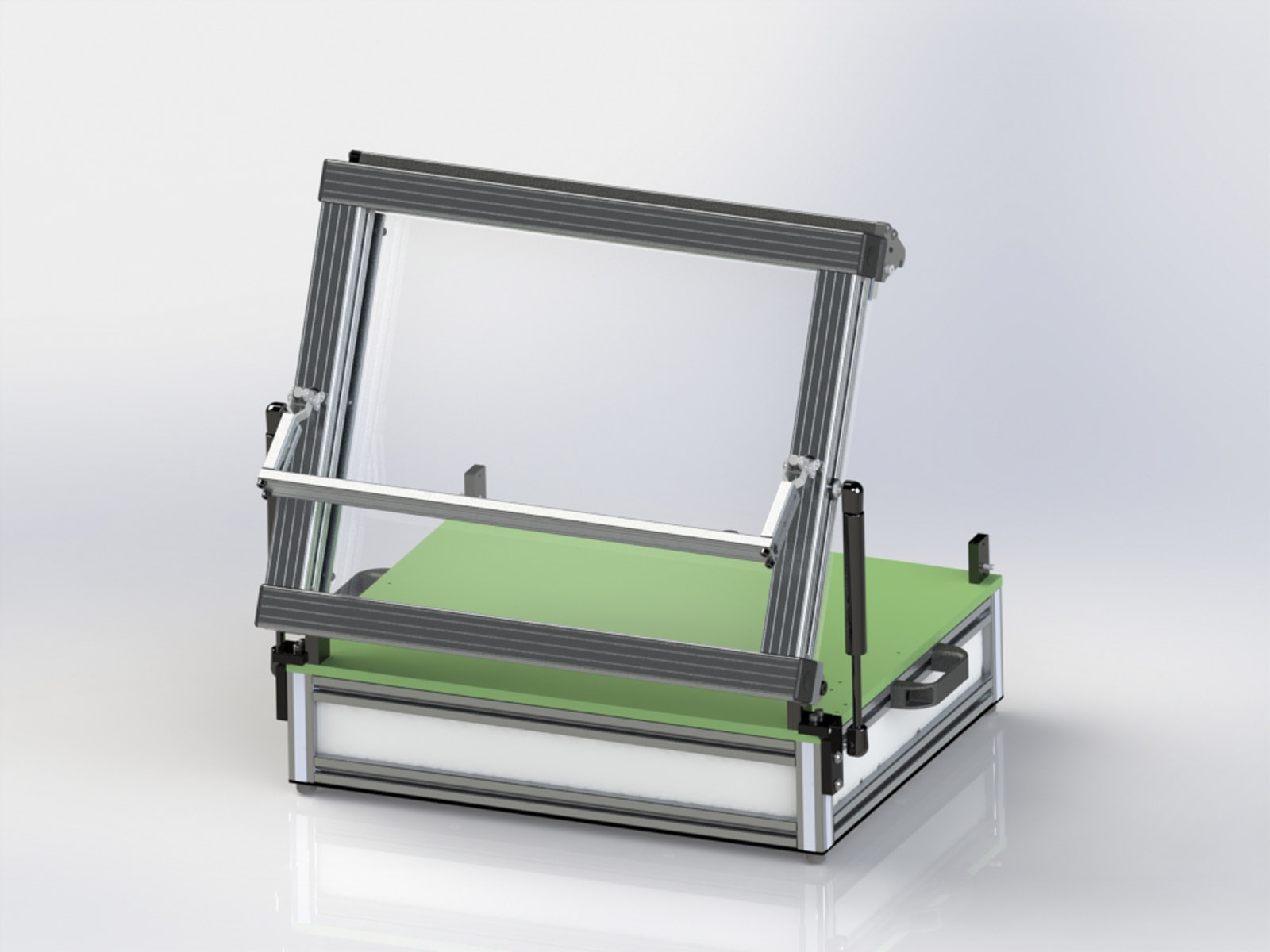

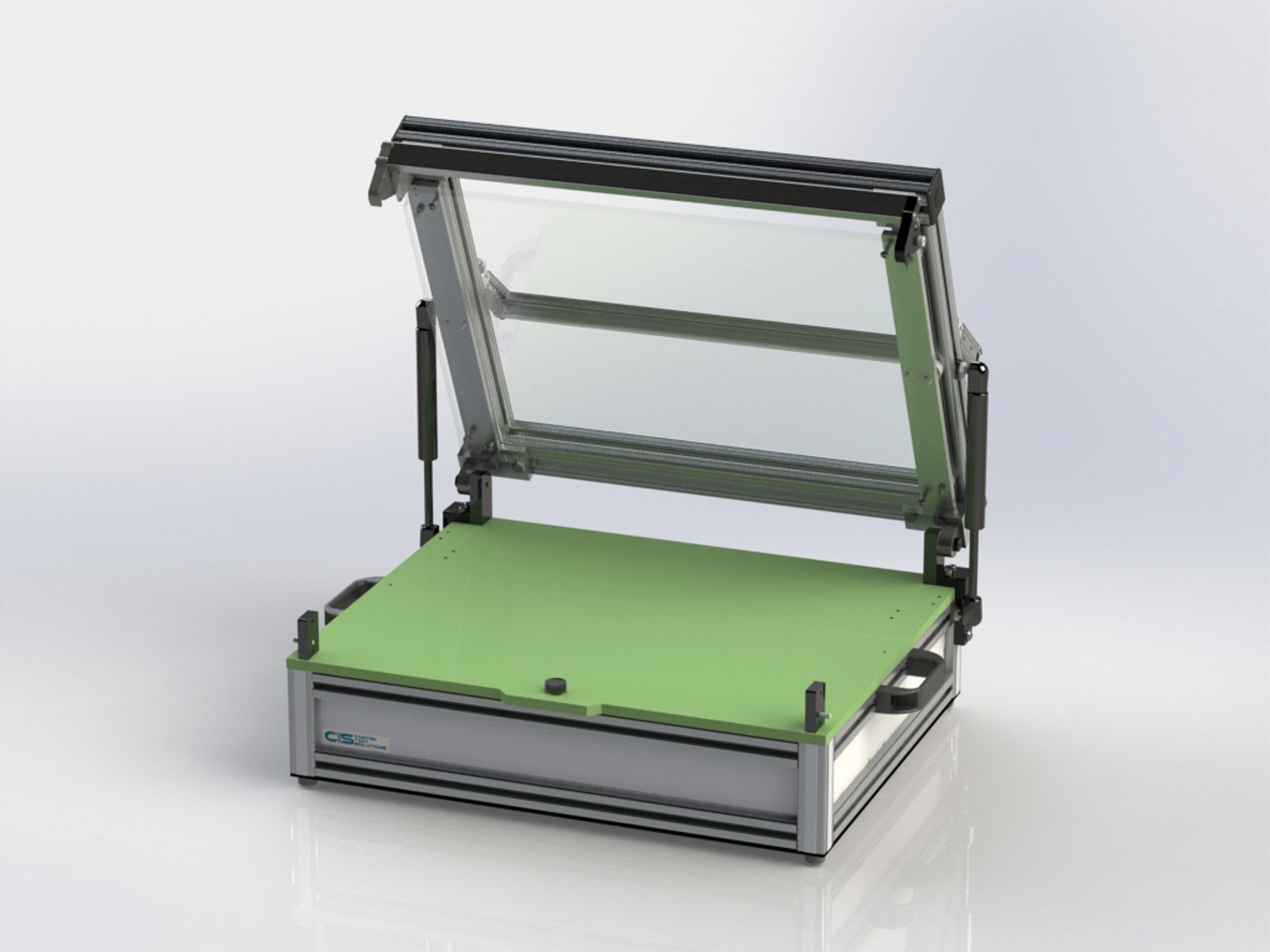

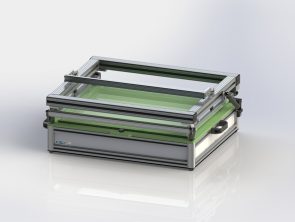

Description

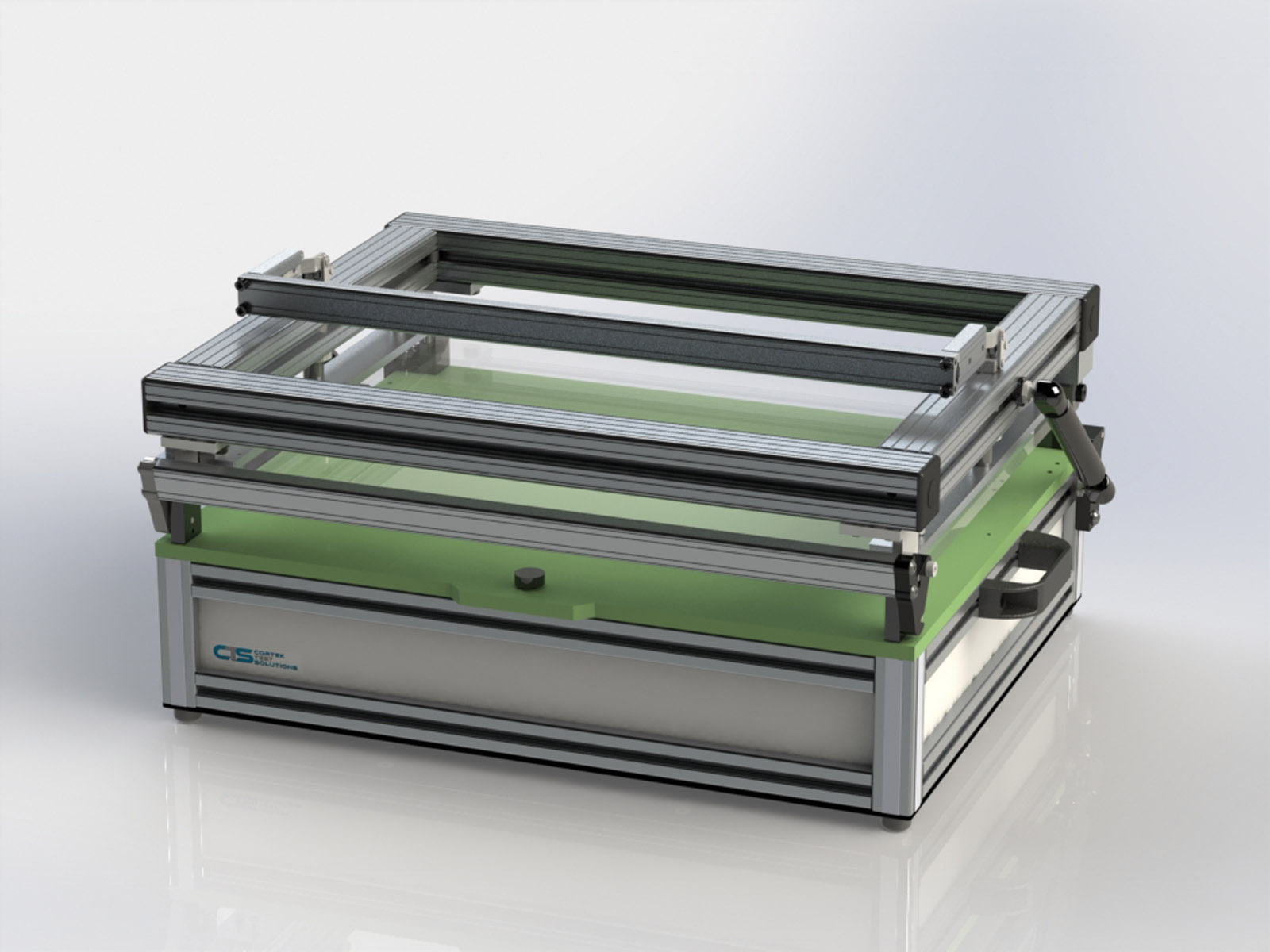

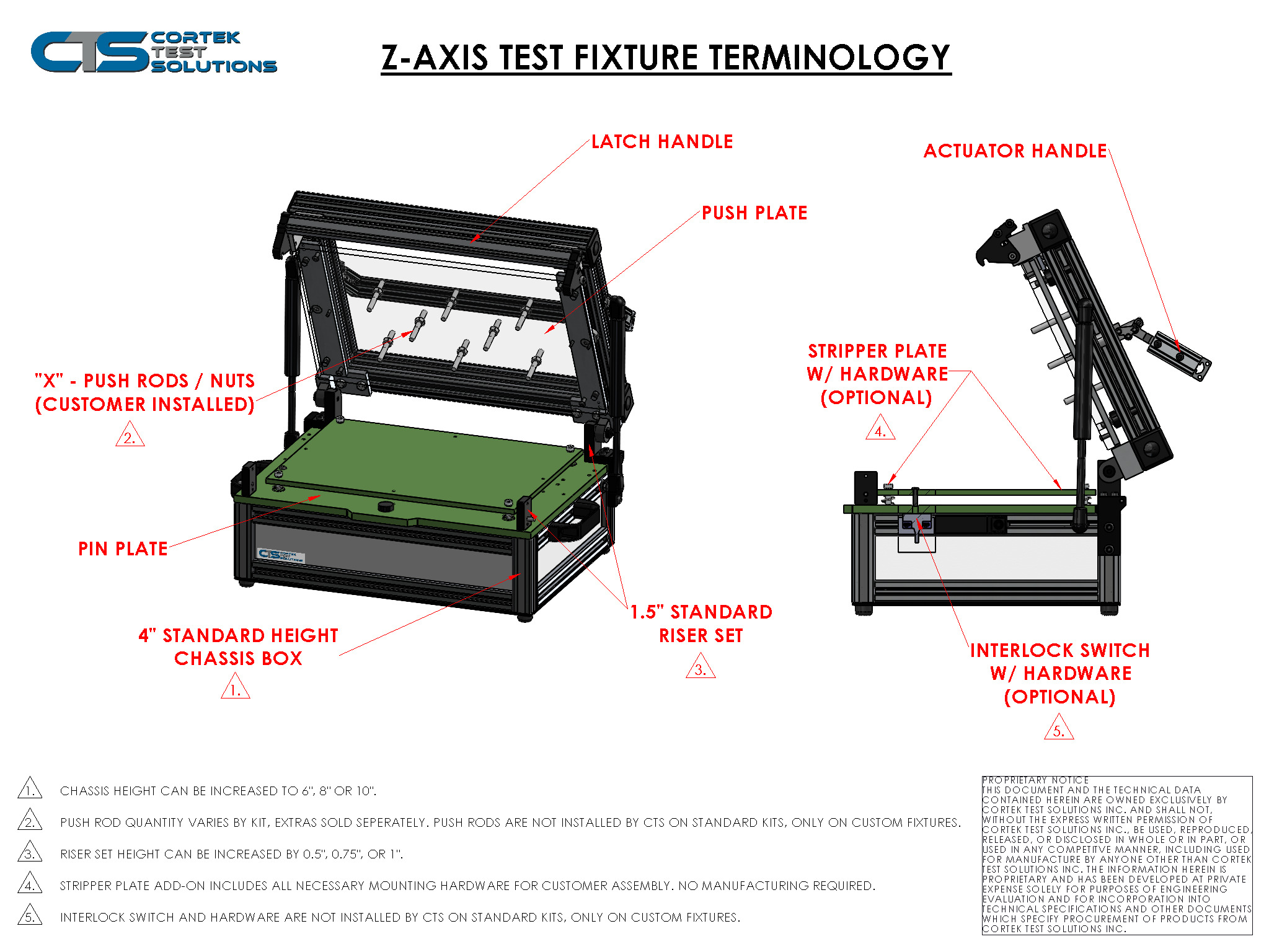

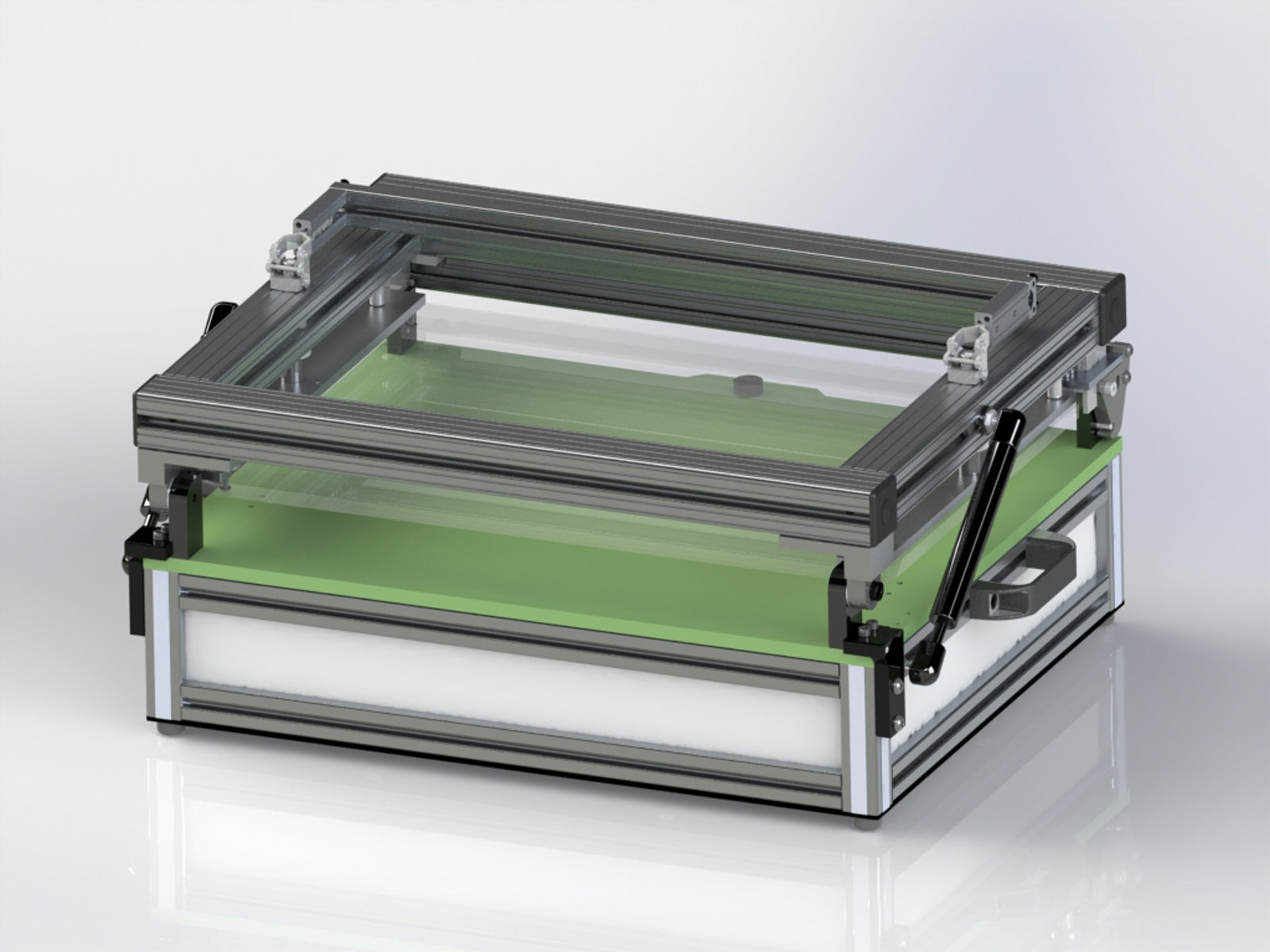

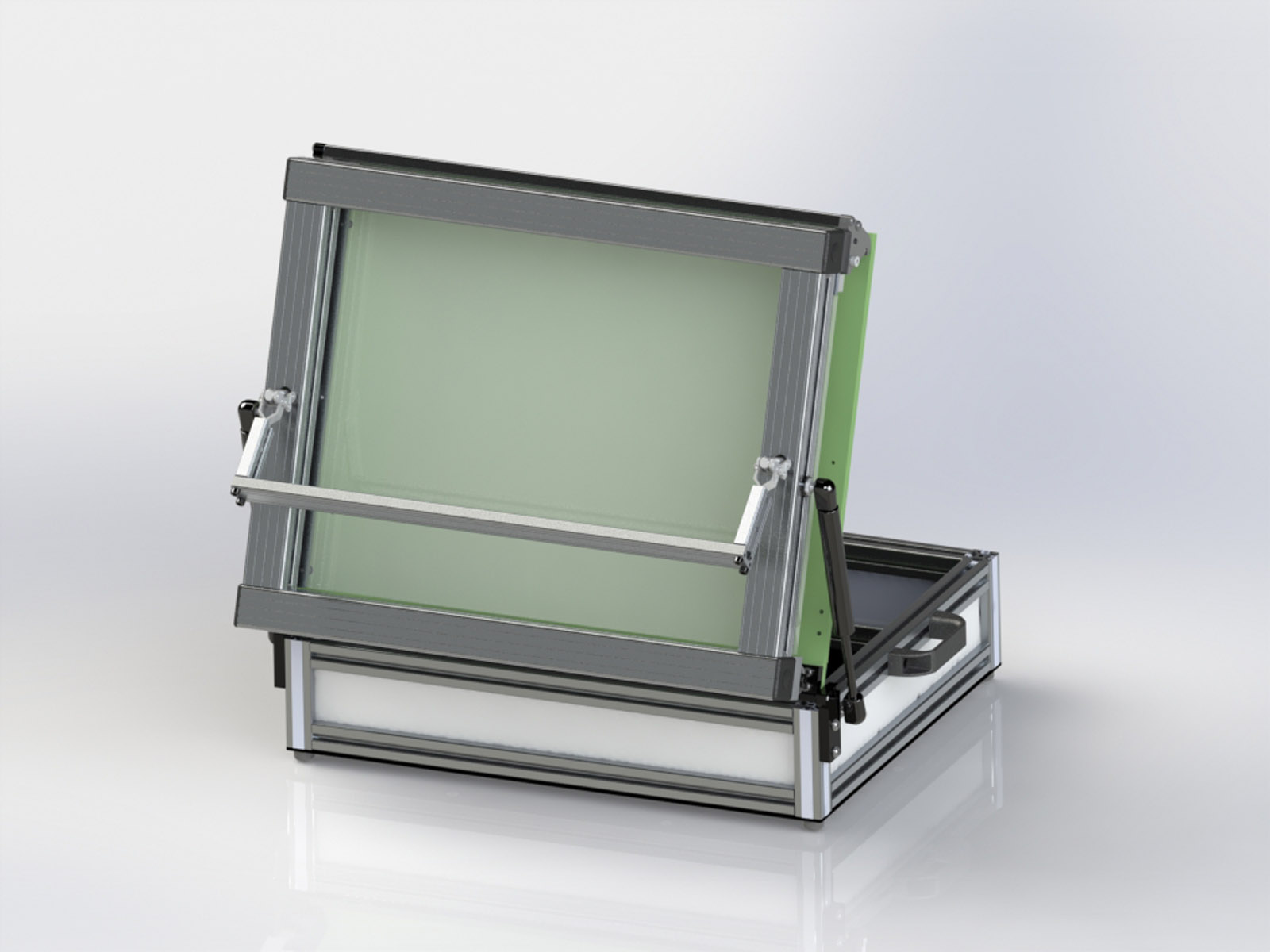

Discover Cortek’s cost-effective Z-axis test fixture kits, the perfect solution for testing printed circuit boards with precise linear engagement in cases where traditional “clamshell” style test fixtures are not appropriate. The Z-Axis assembly seamlessly replaces the standard hinged top push plate in our kits, available in standard sizes. For added convenience, the Z-Axis assembly can be individually purchased for a field upgrade if required. Just like our standard mechanical fixture kits, these units can be easily customized to meet specific size requirements, ensuring flexibility and compatibility for any testing scenario.

Cortek’s Z-axis test fixture kits offer an economical solution for engaging printed circuit boards accurately along the vertical axis when a standard “clamshell” style fixture isn’t appropriate. These Z-Axis assemblies are designed to take the place of the standard top push plates in our kits, and they are available in the typical sizes we offer. Additionally, they can be obtained as standalone assemblies for upgrades to existing setups. Customization is available for these units to meet specific size requirements, maintaining the adaptability of our regular mechanical fixture kits.