PCB Test Fixture Kits

Cortek offers both clamshell style and linear (z-axis) engagement extrusion-based PCB Test Fixtures as a more budget-oriented option for our customer’s functional test fixture requirements. These kits come in a variety of sizes and can be used in many of the same applications as the Mechanical Presses.

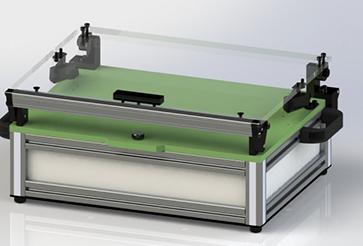

PCB Test Fixture Kit #0608

The PCB Test Fixture Kit 0608 design is clean, compact and rugged, and easily adaptable. This small-sized test fixture is used for printed circuit board testing to economically test your smaller sized PCBs.

- UUT Test Area: (W X D X H): 4.0” x 6.0“ x 2.0” (UUT may extend beyond test area)

- Overall Dimensions: (W X D X H): 9.9” x 8.9” x 7.7” (dimensions include handles, hinges)

- Weight: Approximately 7 lbs.

- Hinged, no internal springs

- Includes 6 ESD pushers/nuts

PCB Test Fixture Kit #1208

The 1208 PCB Test Fixture has a usable test area that is large enough to accommodate a multitude of the most commonly sized printed circuit boards requiring functional board testing. This small-sized bed of nails test fixture provides more usable testable area for the unit under test compared to competition.

- Design is clean, streamlined and rugged

- UUT Test Area: (W X D X H): 9.0” x 6.0“ x 2.0” (UUT may extend beyond test area)

- Overall Dimensions: (W x D x H): 14.9” x 8.9” x 7.7” (dimensions include handles, hinges)

- Weight: Approximately 11 lbs.

- Spring assisted push plate and pin plate for easier wiring and access to chassis compartment.

- Includes 8 ESD pushers/nuts

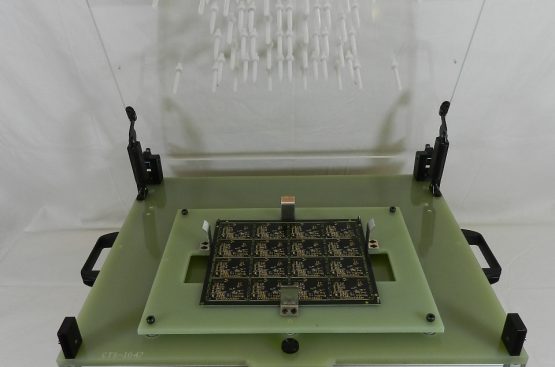

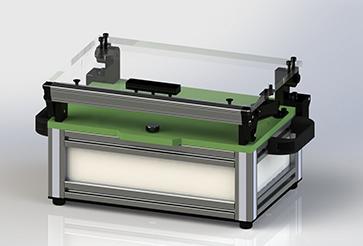

PCB Test Fixture Kit #1612

The 1612 Test Fixture Kit provides a usable test area to accommodate PCBs up to a foot long while still being a very cost-effective bed of nails platform as compared to other kits of similar capabilities. This easily customizable unit is among the most popular of our functional test fixture kits for its very capable test area and chassis box compartment large enough for a variety of peripheral testing devices.

- Test Area up to 12.0″ x 10.0″ x 2.0″

- Overall Dimensions: (W x D x H): 17.9” x 12.9” x 7.7”

- Weight: Approximately 18 lbs.

- Ease of side panel fabrication for I/O connections, switches or other hardware.

- Includes 12 ESD pushers/nuts

- Spring assisted push and pin plate for easy access kit internals.

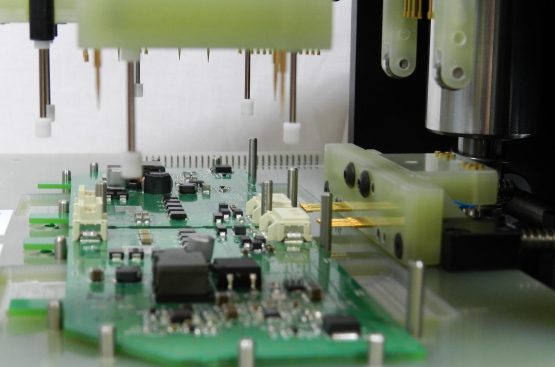

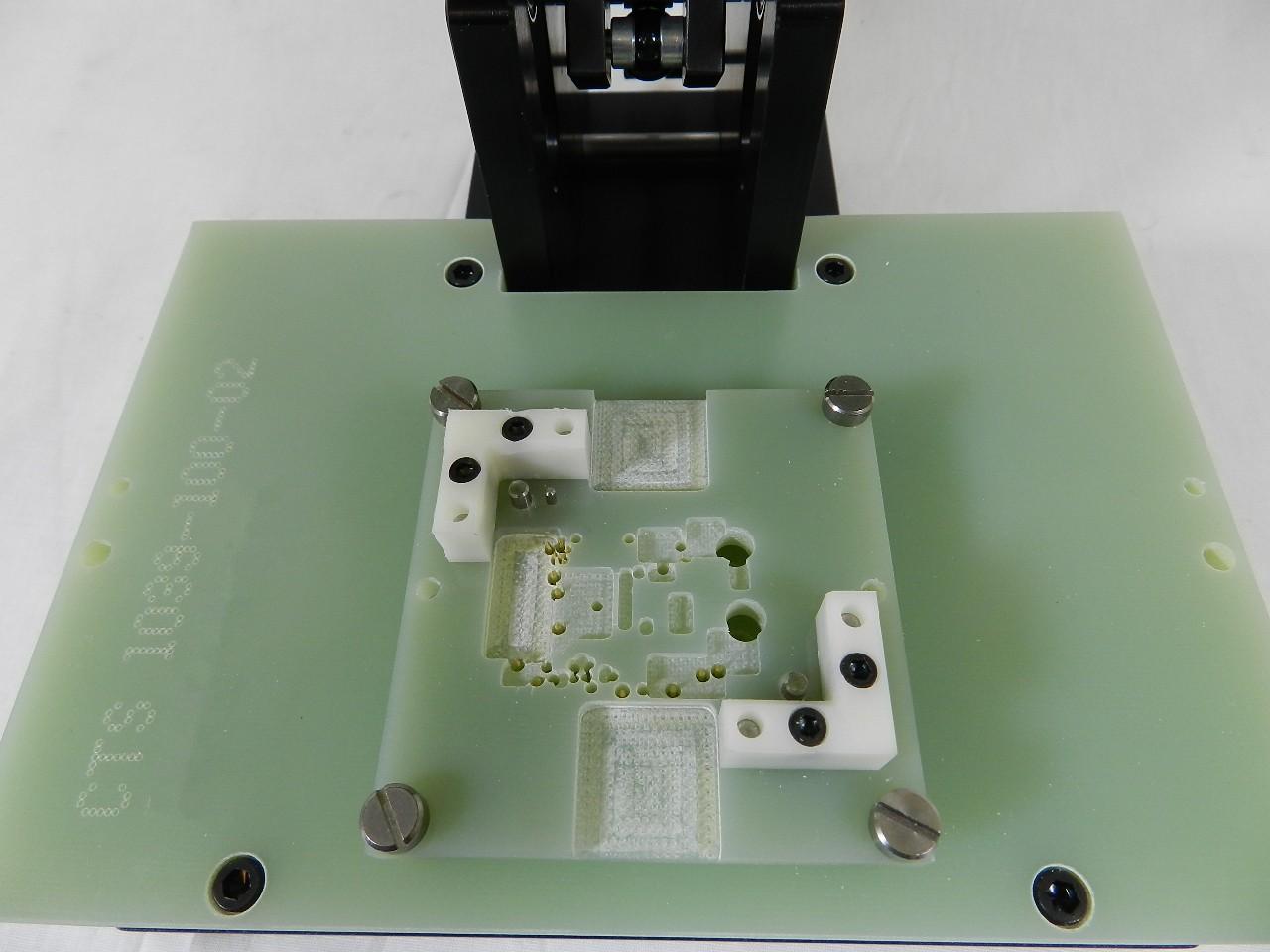

Mechanical Presses and Flip-Top Press Text Fixture Kits

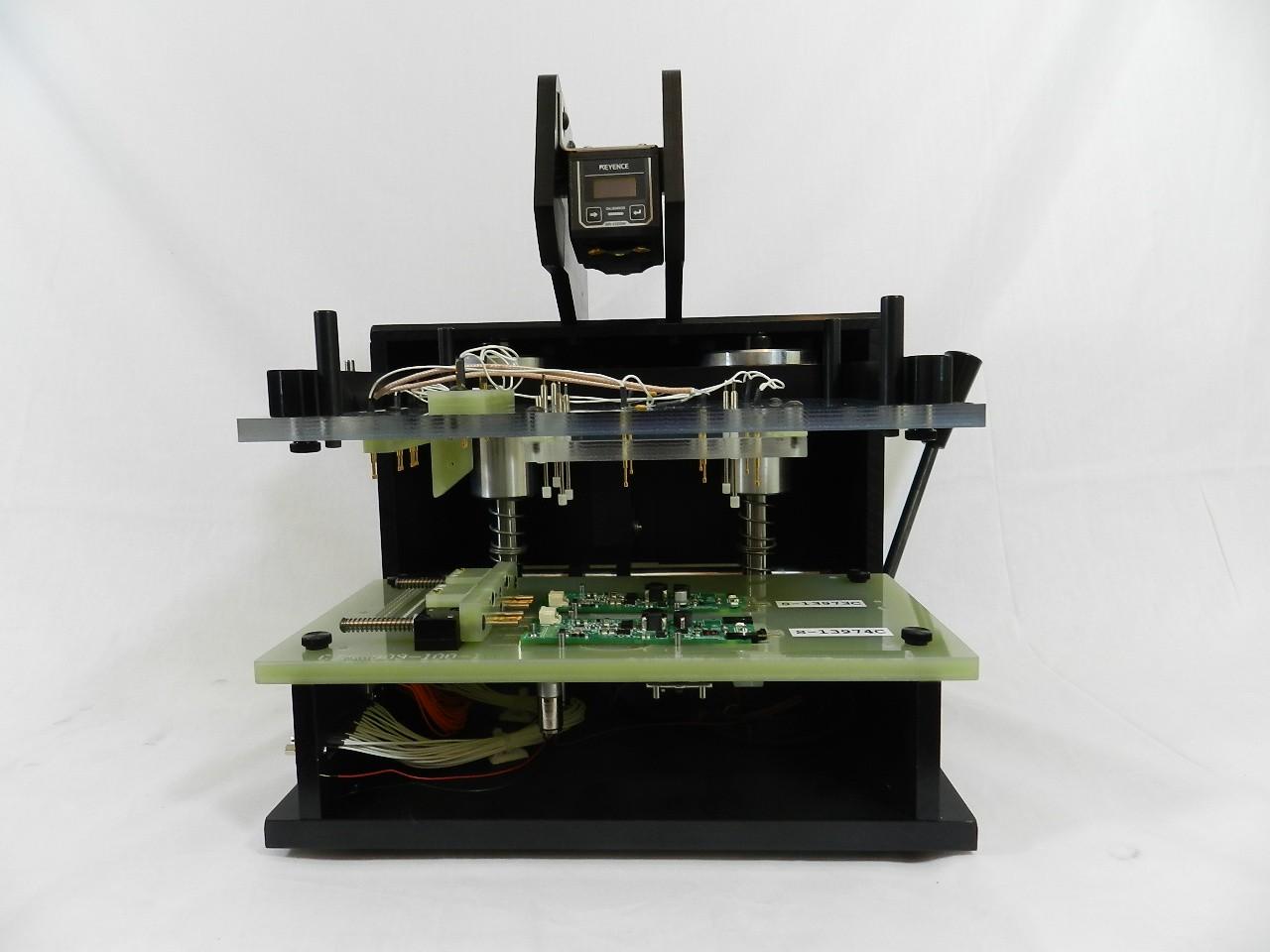

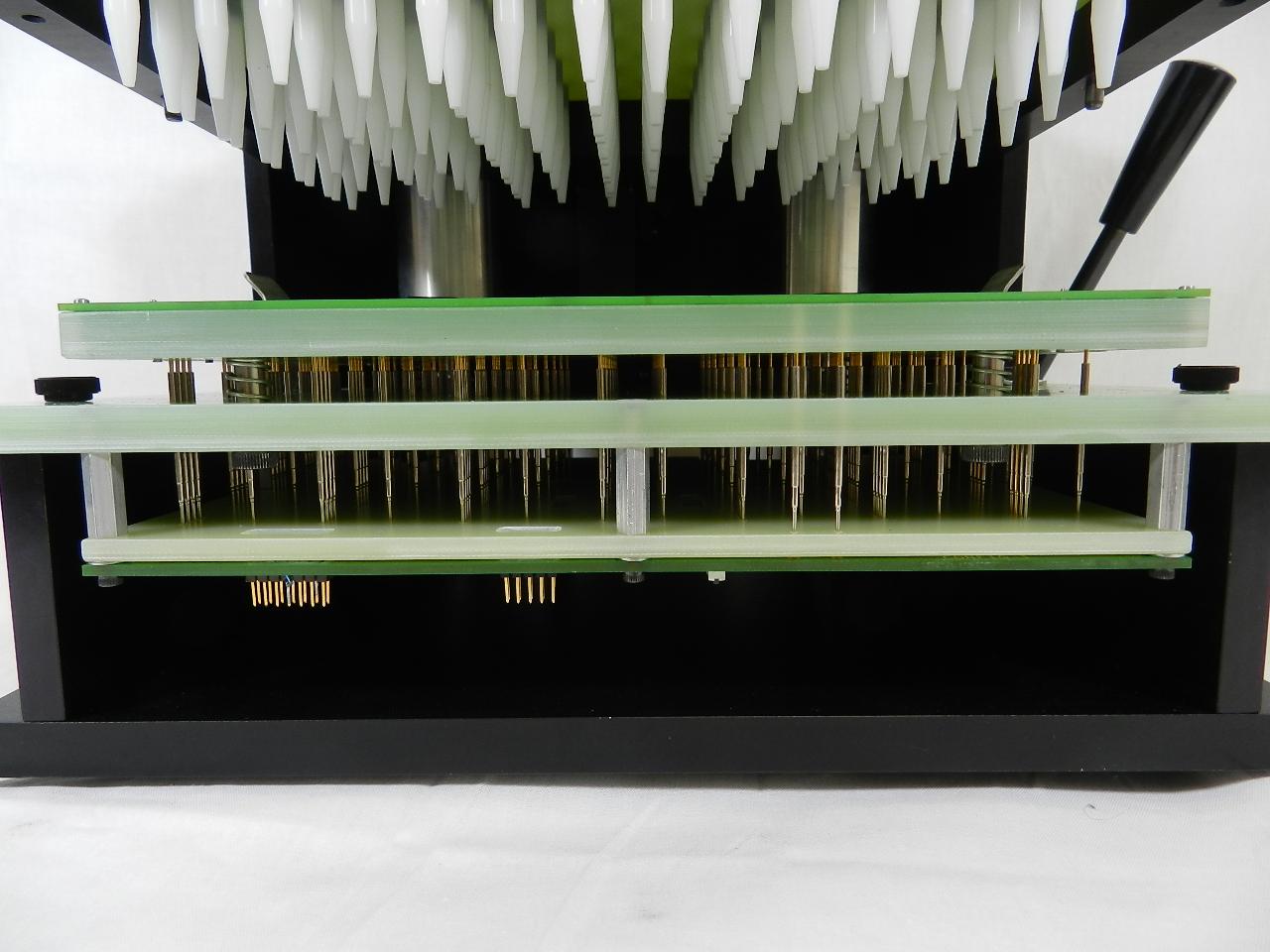

Cortek’s legacy line of mechanical presses is a highly accurate, repeatable and re-useable test fixture platform. They were designed to provide simultaneous top and bottom side probing when testing printed circuit boards (PCBs) and the also offers side access probing capability. More Design Information.

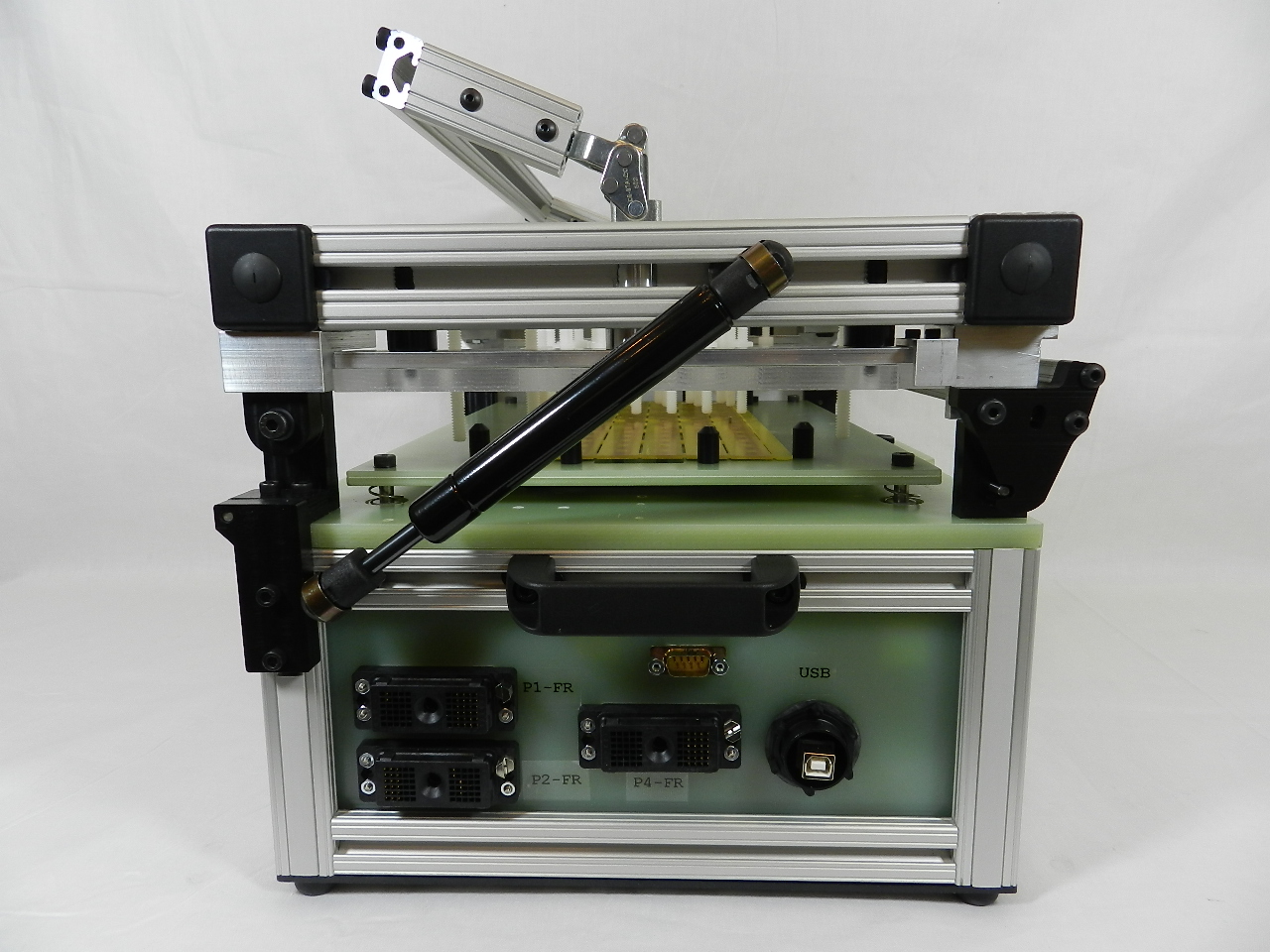

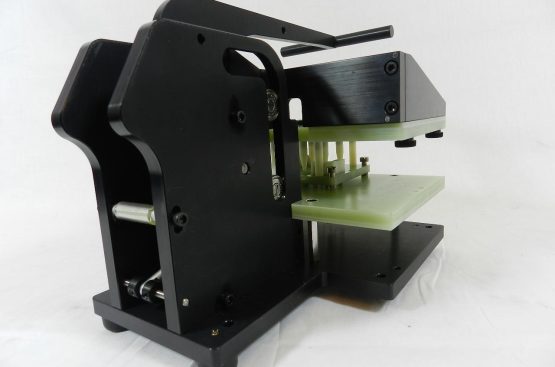

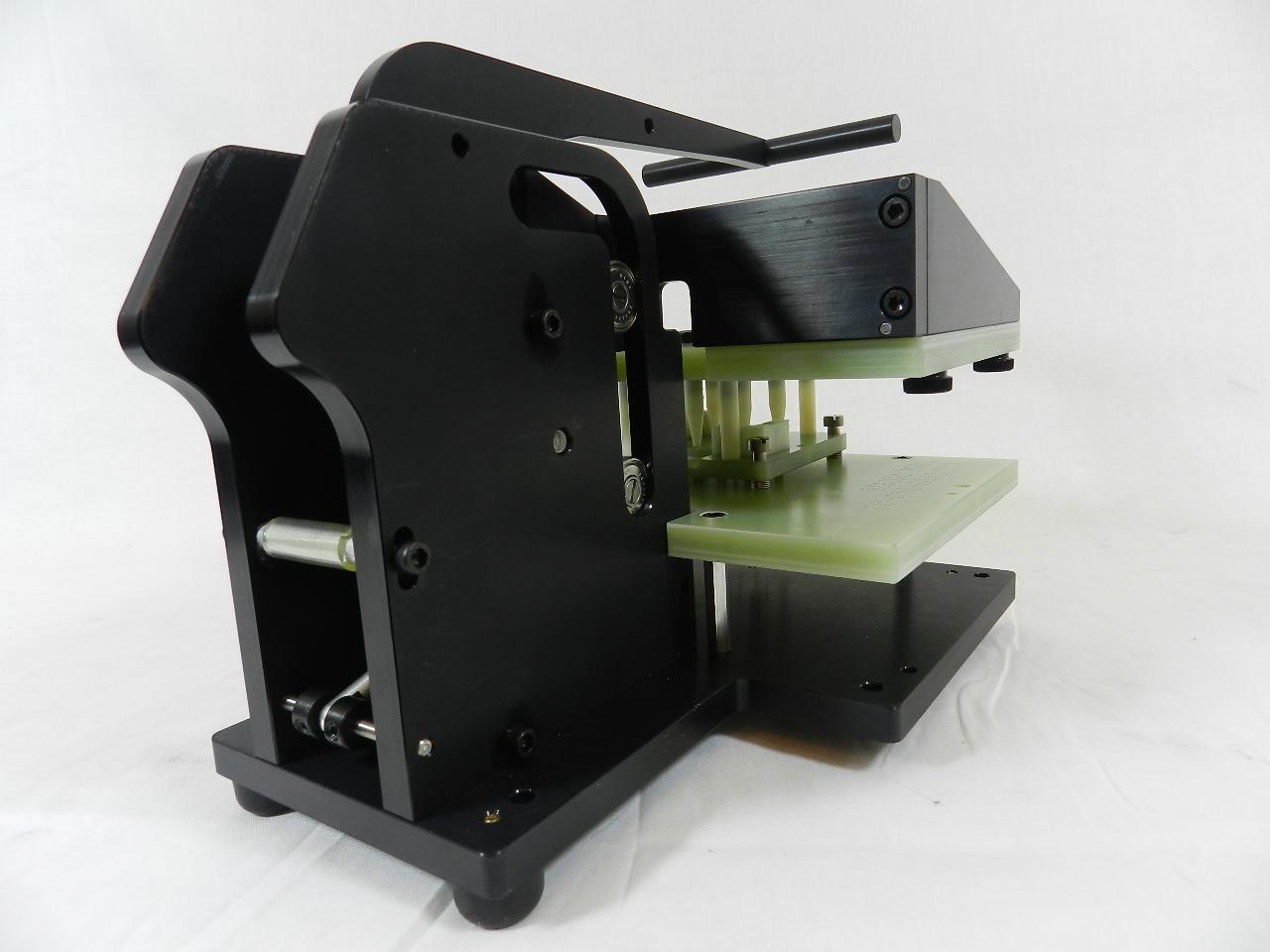

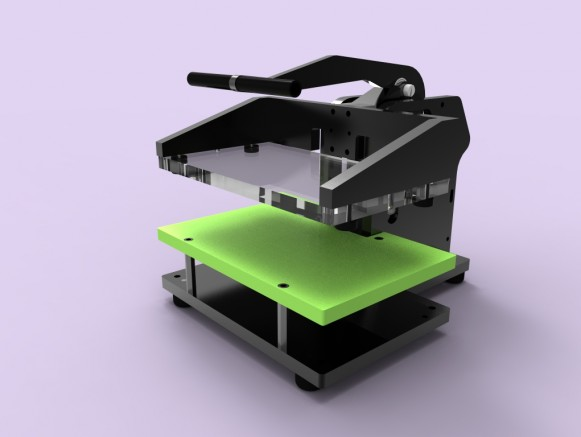

Flip Top Mechanical Press #7540

The Flip Top press offers precise linear motion that guarantees reliable contact between the test pins and UUT when a fixture is properly designed.

- Interchangeable top & bottom plates

- Mechanical operation

- Cam Follower

- Linear Vertical Actuation

- Top and Bottom side probing

- Black Anodized 6061 Aluminum

- Upper plate flips out of place when opened for ease of seating UUT for test.

- Small footprint ideal for limited space

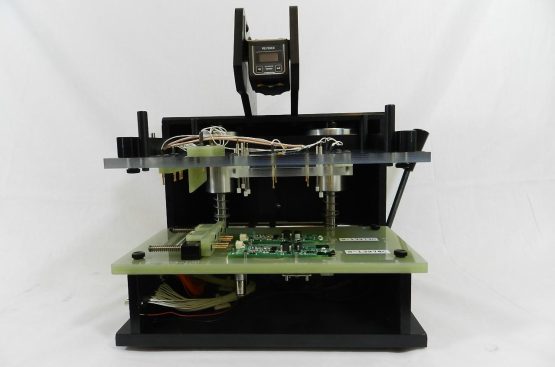

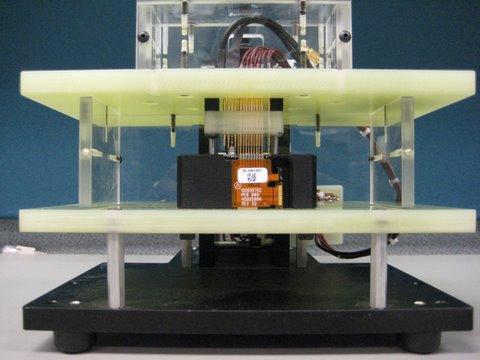

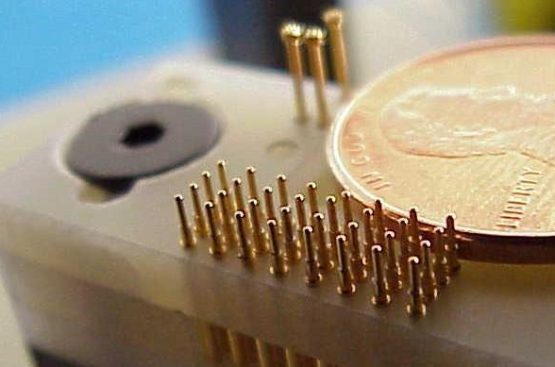

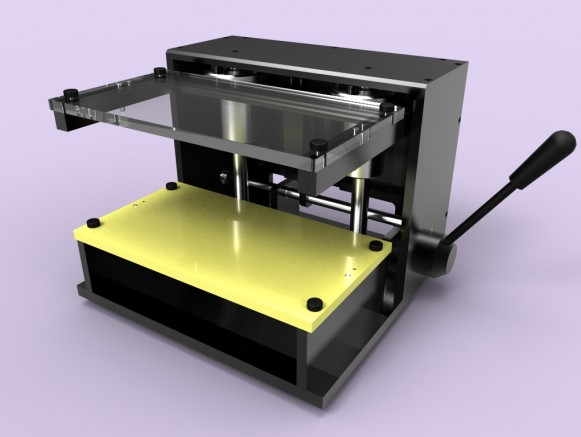

Reusable Mechanical Press #9560

The true benefit of this mechanical press is it offers the versatility to change out fixture plates enabling the customer to test multiple products on the same fixture kit thus making it a cost effective solution that also standardizes your test set up.

- Interchangeable top & bottom plates

- Mechanical operation

- Linear vertical actuation

- Top and Bottom side probing and access

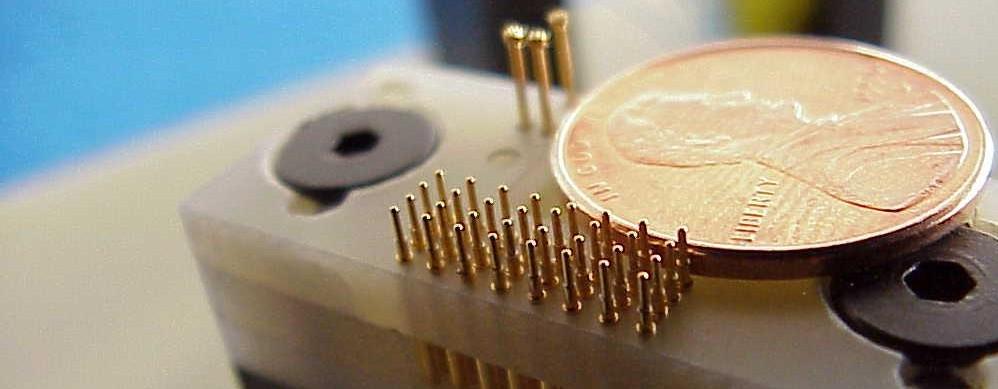

- Fine pitch probing

- Solid Aluminum and Steel Construction

- High Level of Accuracy, Repeatability, Durability, Reliability

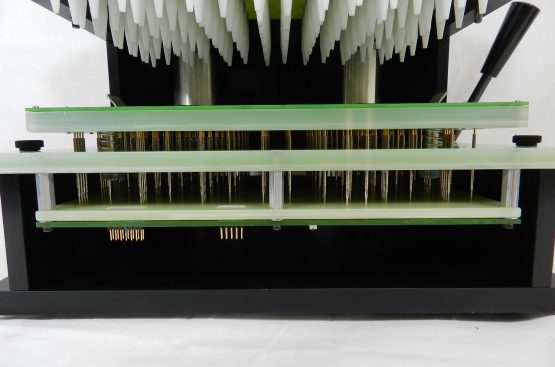

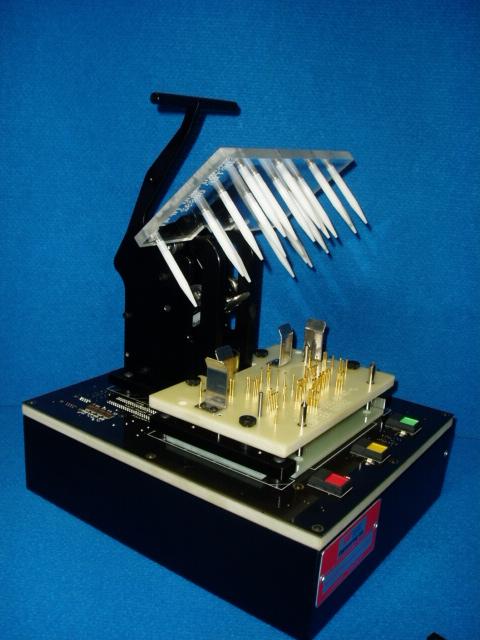

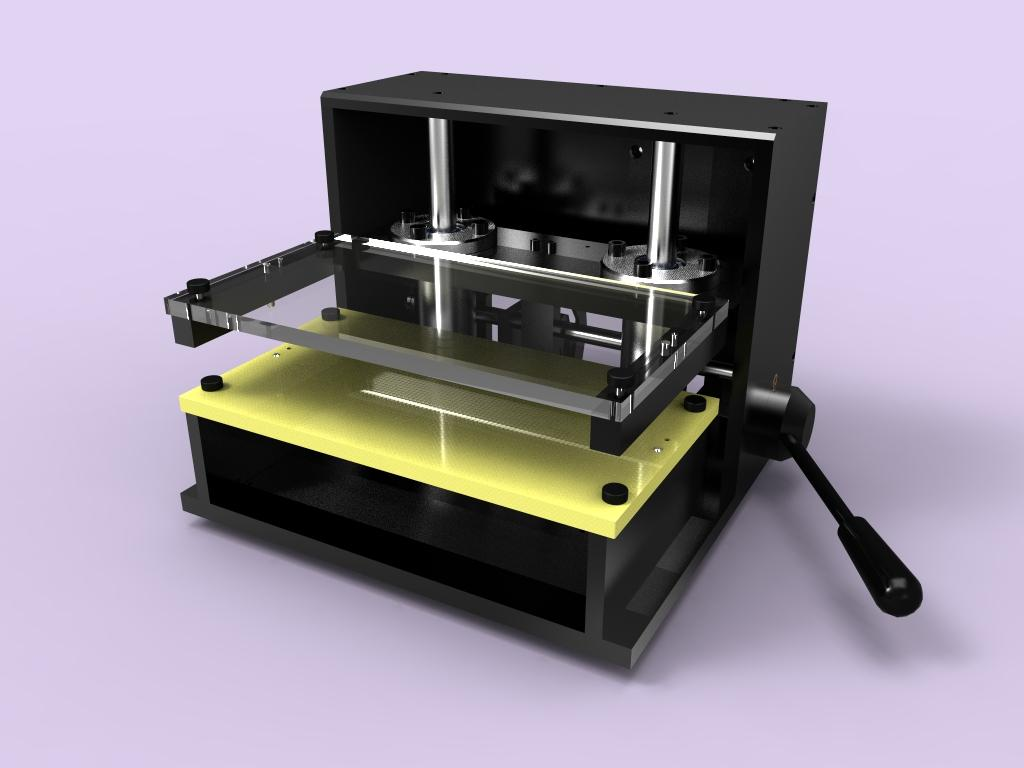

Reusable Mechanical Press #1012

This mechanical press is designed to provide precise, bed-of-nails contact in both R & D and production environments. Durable aluminum and steel construction, precision bearings and hardened steel.

- Interchangeable top & bottom plates

- Mechanical operation

- Linear vertical actuation

- Top and Bottom side probing and access

- Fine pitch probing

- Solid Aluminum and Steel Construction

- High Level of Accuracy, Repeatability, Durability, Reliability

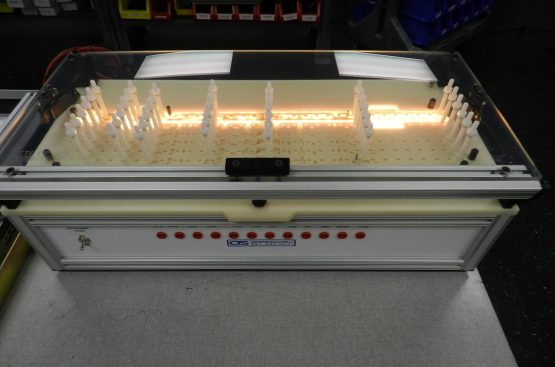

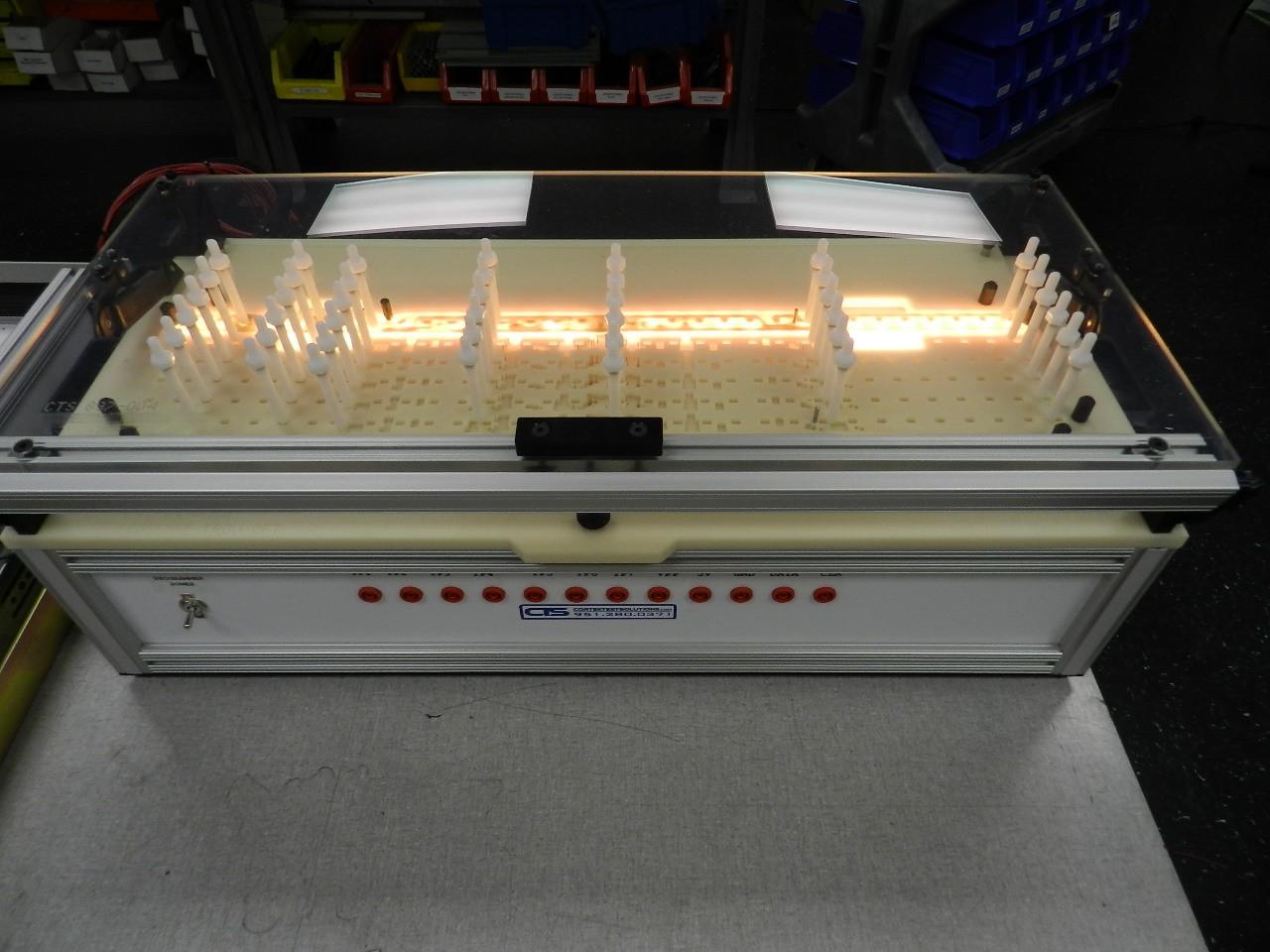

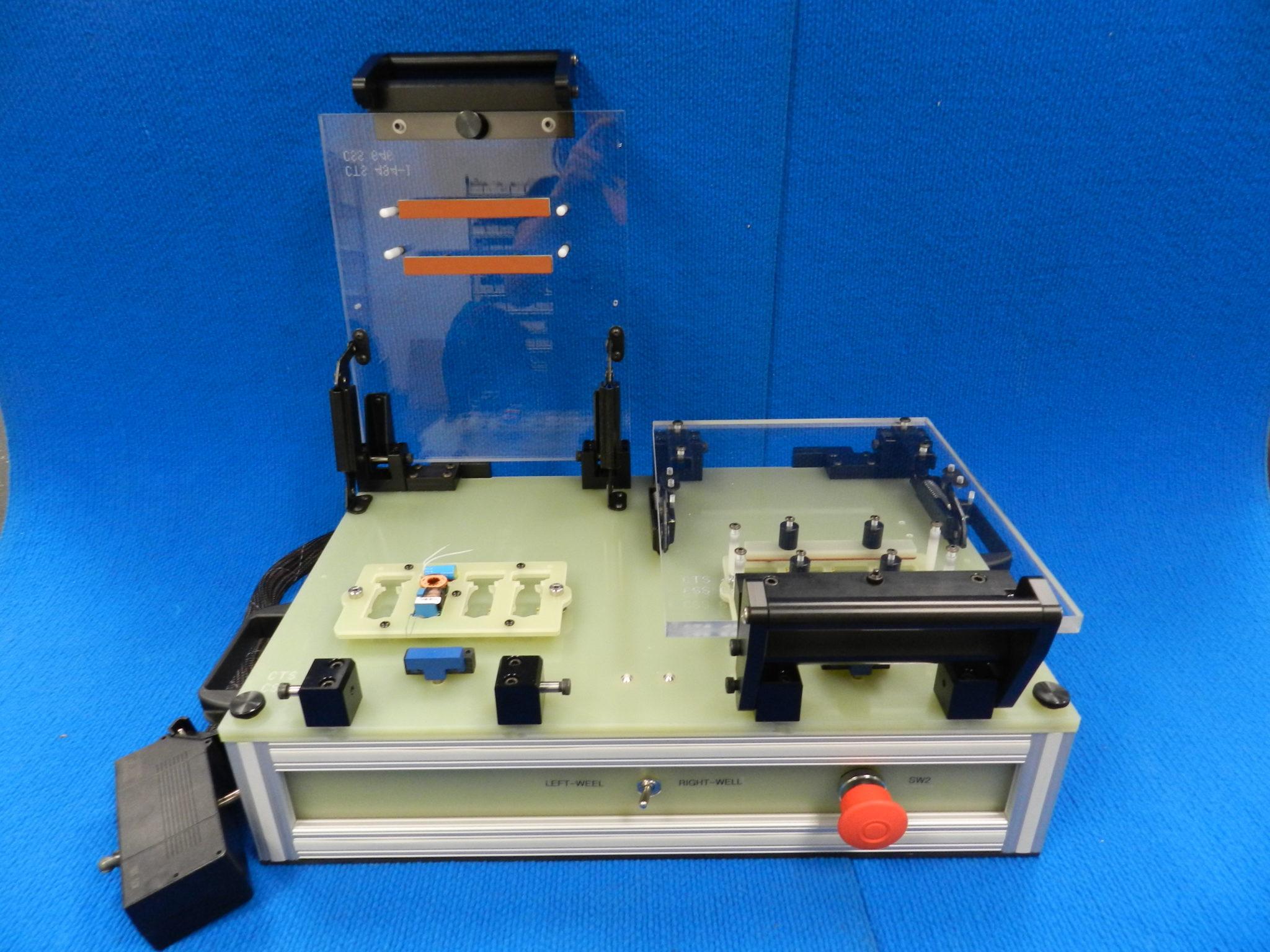

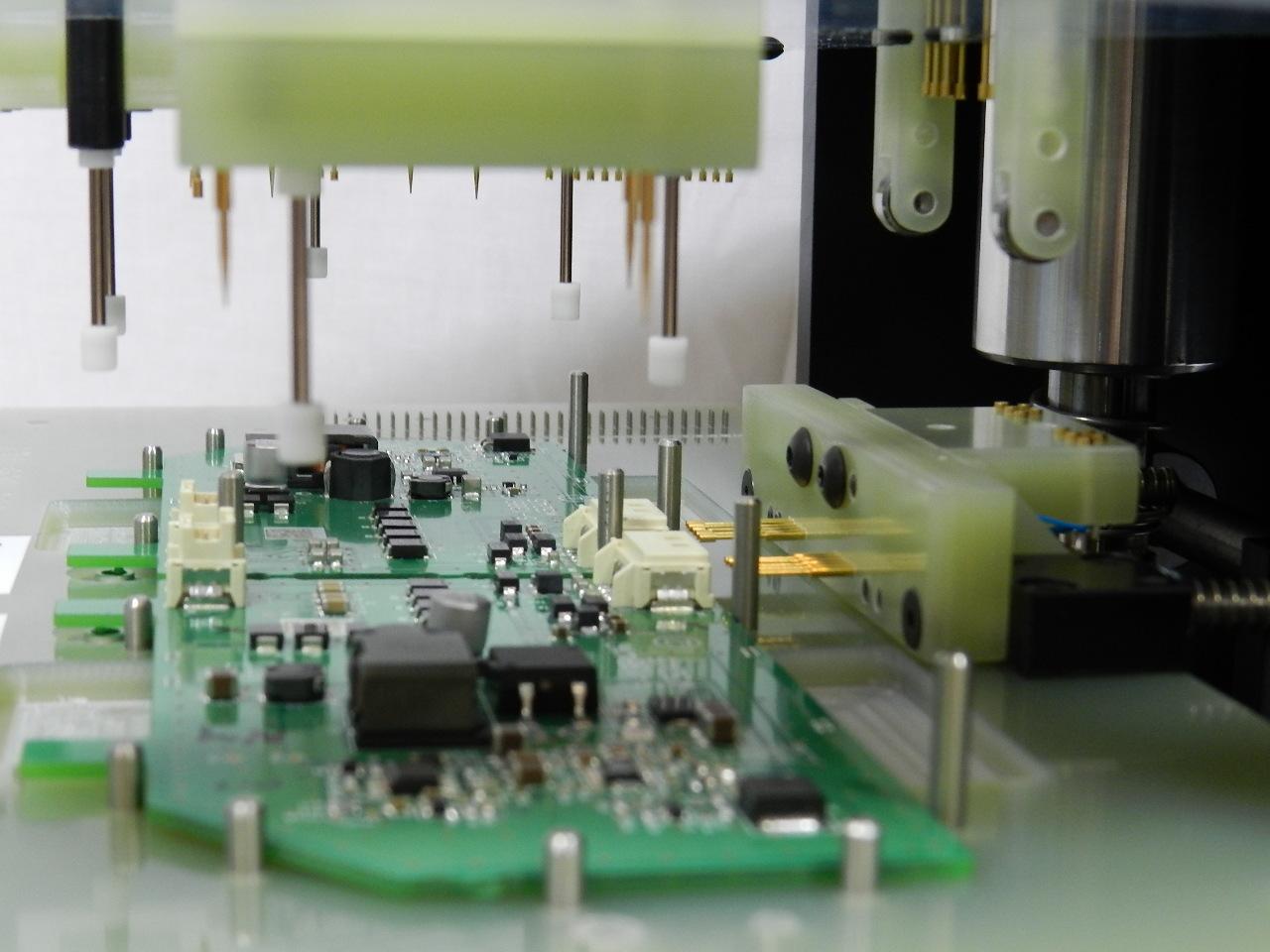

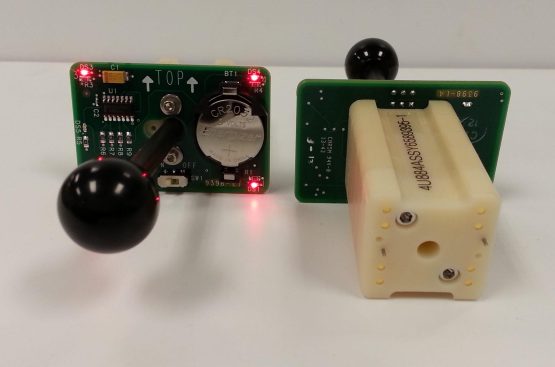

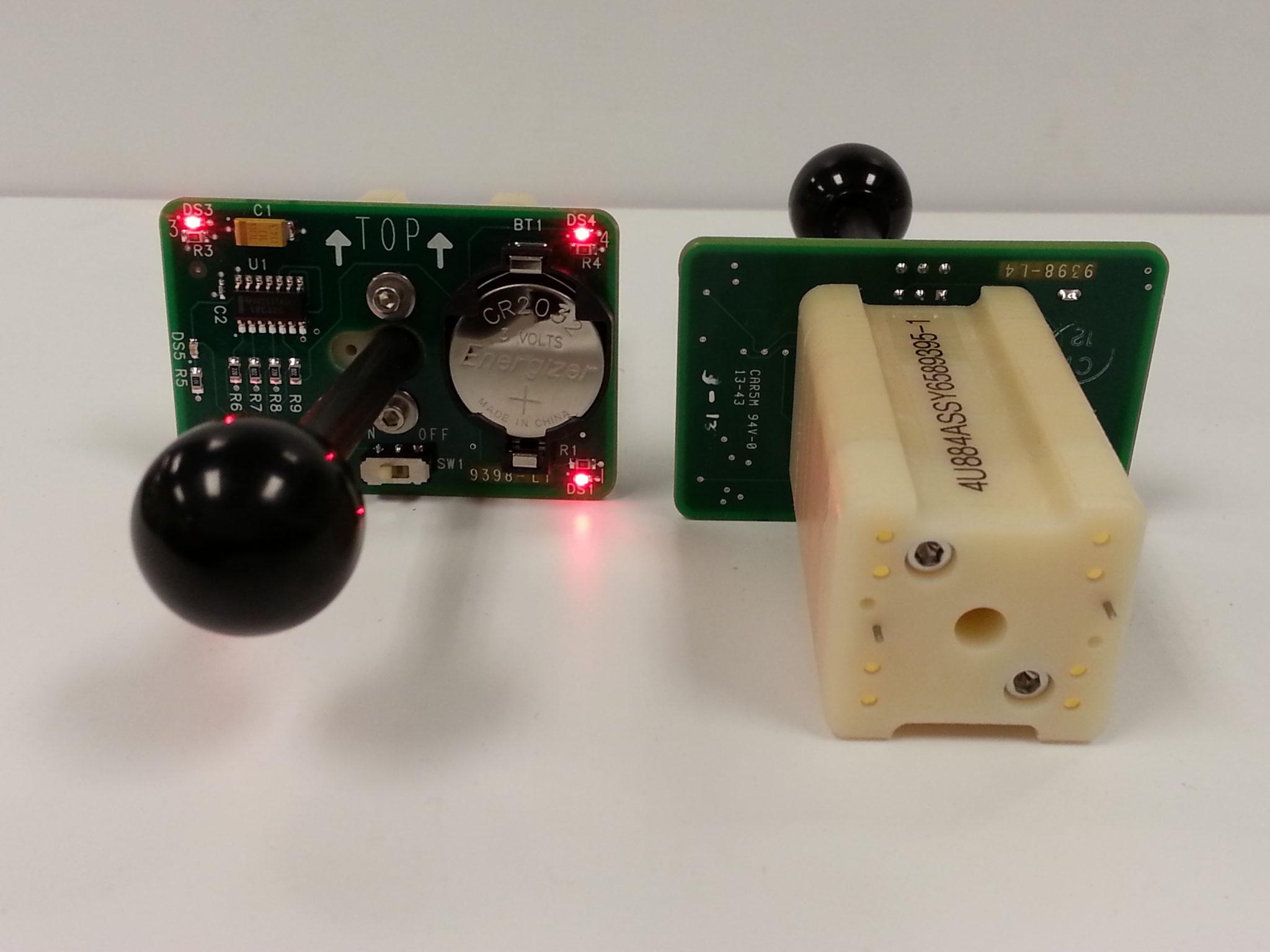

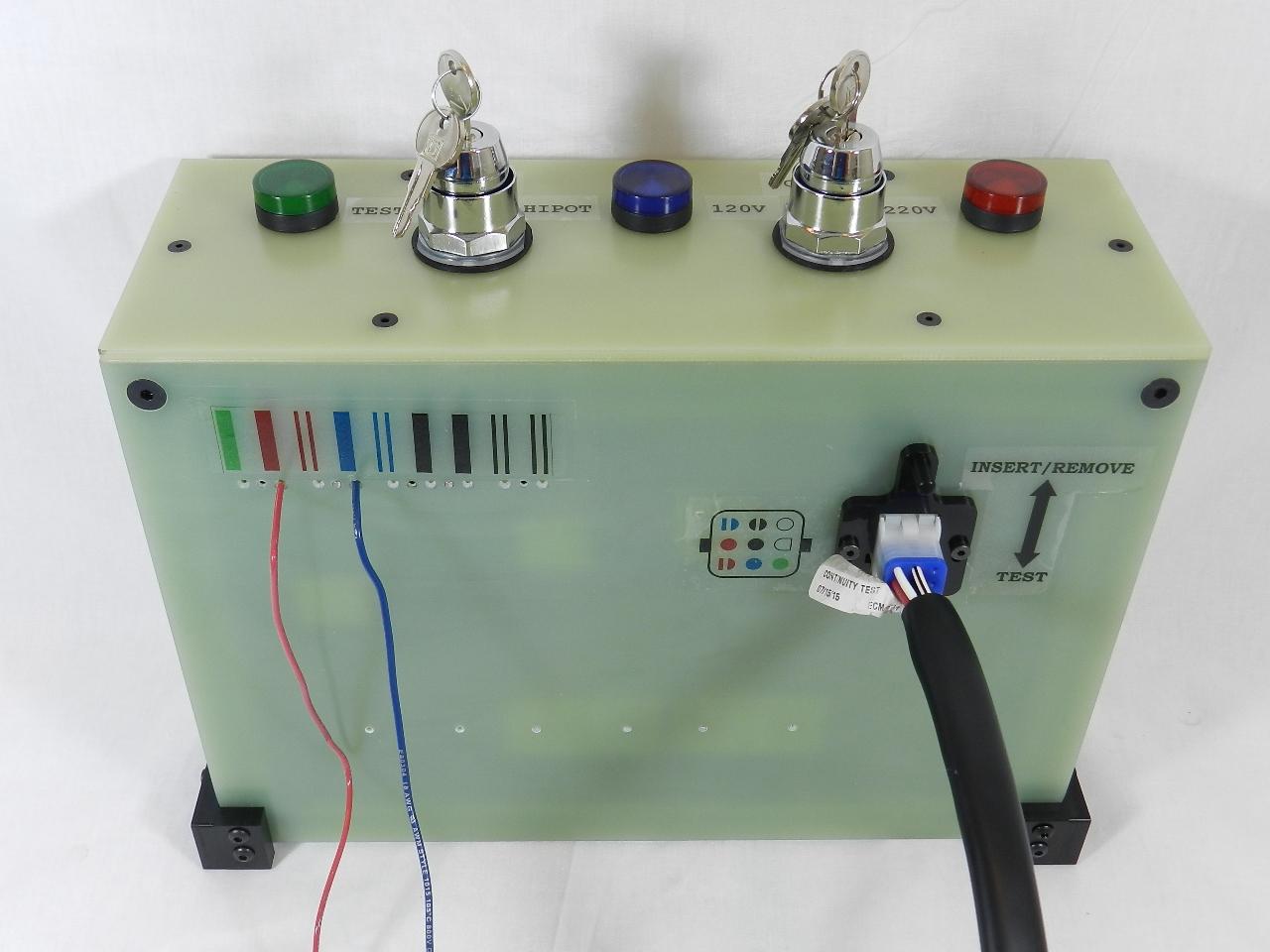

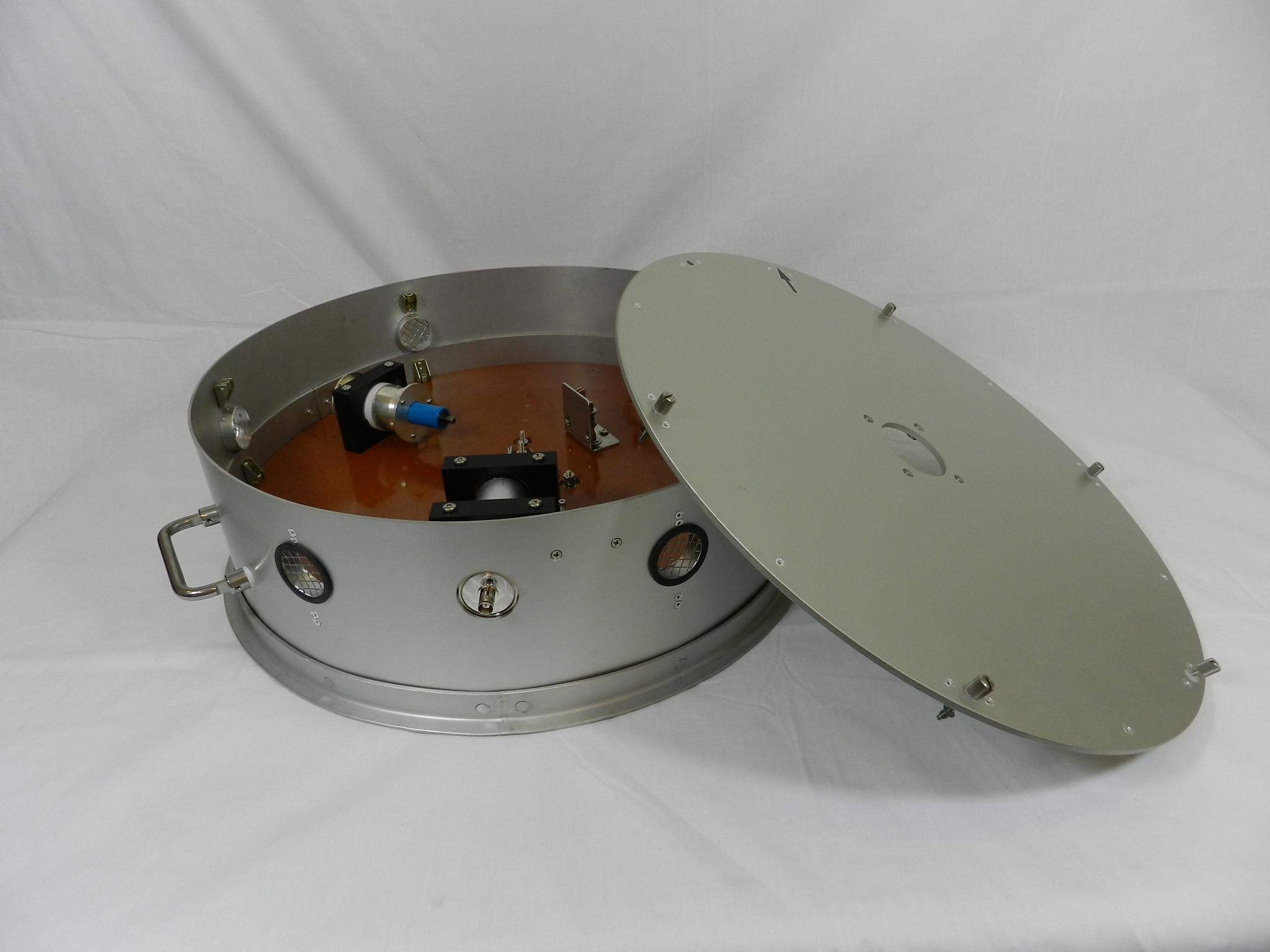

Custom Test Fixtures

Cortek specializes in creating custom solutions for test fixture units that require functional testing. Our team designs and manufactures a machine to test each of our customers needed requirements. Our functional test kits offer flexibility and robust features and come in a variety of sizes. From simple mechanical test fixtures, to intricate functional test units that interface with test software, CTS will provide the solution needed to get the job done.

Z-Axis Test Fixture Kits

Clamshell (non Z-Axis) Test Fixture Kits

Mechanical Presses

Flip-Top Presses

Fully Custom Units