Mechanical Press Information

WHAT IS IT?

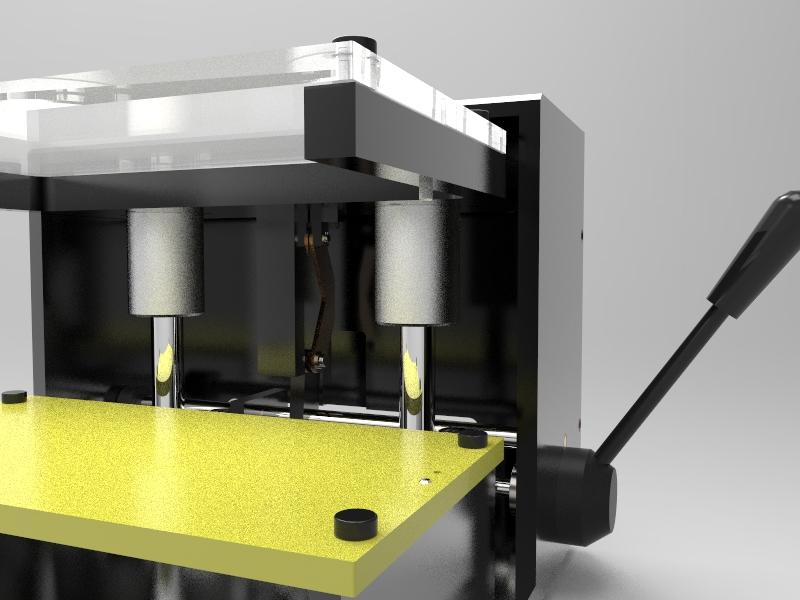

Our press is a manually operated machine. It precisely moves an upper clamp plate in the Z axis 2 7/8” with a force multiplying mechanism. The clamp plate utilizes a set of four sealed cage bearings aligned to two precision machined ¾” diameter bearing shafts.

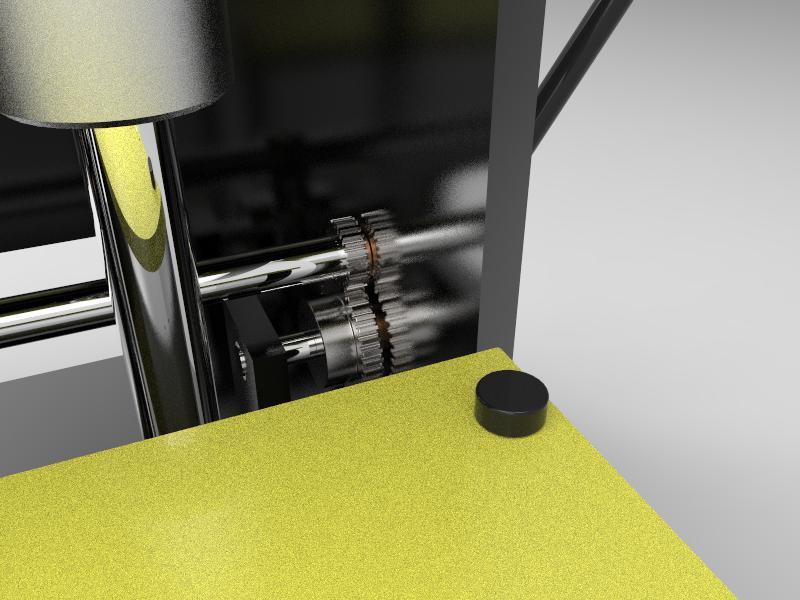

Actuation of the press is accomplished with a side lever. Operator pressure is multiplied through a set of gears and a toggle link mechanism.

WHY IS THE DESIGN IMPORTANT?

Whether you’re testing one hundred devices or one hundred thousand you need precise repeatability. Every time the press is actuated you know that your fixture design will not be compromised due to a low quality mechanism. Sealed bearings are used so that environmental conditions won’t deteriorate the precision bearings or shafts. Four sets of bearings are used so that fixtures that cause unequal forces won’t force the press out of alignment or cause binding. Our manual gear driven toggle design ensures that fixtures with high or low force requirements will have little effect on the person operating the mechanism. If you need top, bottom, side access or all axis at the same time our linear presses are up to the task due to the robust design.

COST AND BENEFITS

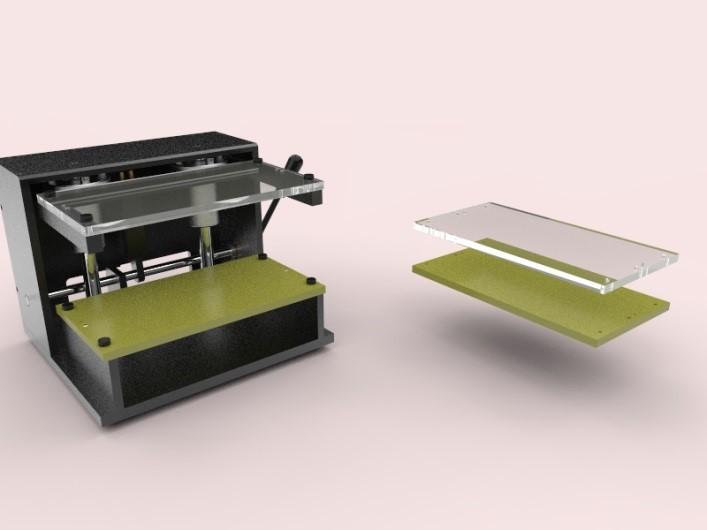

Our presses are a platform that can be switched between multiple fixtures without employing tools. Top and bottom fixture plates are each held in place with four thumb screws. Operators don’t require special skills or tools to quickly setup for a different UUT fixture.

New fixtures start with a set of very inexpensive fixture plates. Since the actuating hardware is all contained within the press you’re not purchasing duplicate mechanical devices over and over again. Inexpensive fixture kits retain all of the precision, flexibility and longevity of other fixturing systems at a fraction of the cost.

When new fixture requirements come up you can focus on creating the fixture you really need because you’re not limited by the fixture activation method. Competing designs, due to mechanical design limitations, may lack the accuracy of our press and/or the torque multiplying activation system which can suppress the ability to make the best possible electrical contact. Choosing lower test pin spring pressures or eliminating electrical contacts because of mechanism design limitations in effect dumbs down test fixtures.

Due to the compact innovative press design you don’t need electrical, pneumatic or vacuum lines and solenoids to actuate the fixtures. There are no consumables required and maintenance is almost nonexistent.