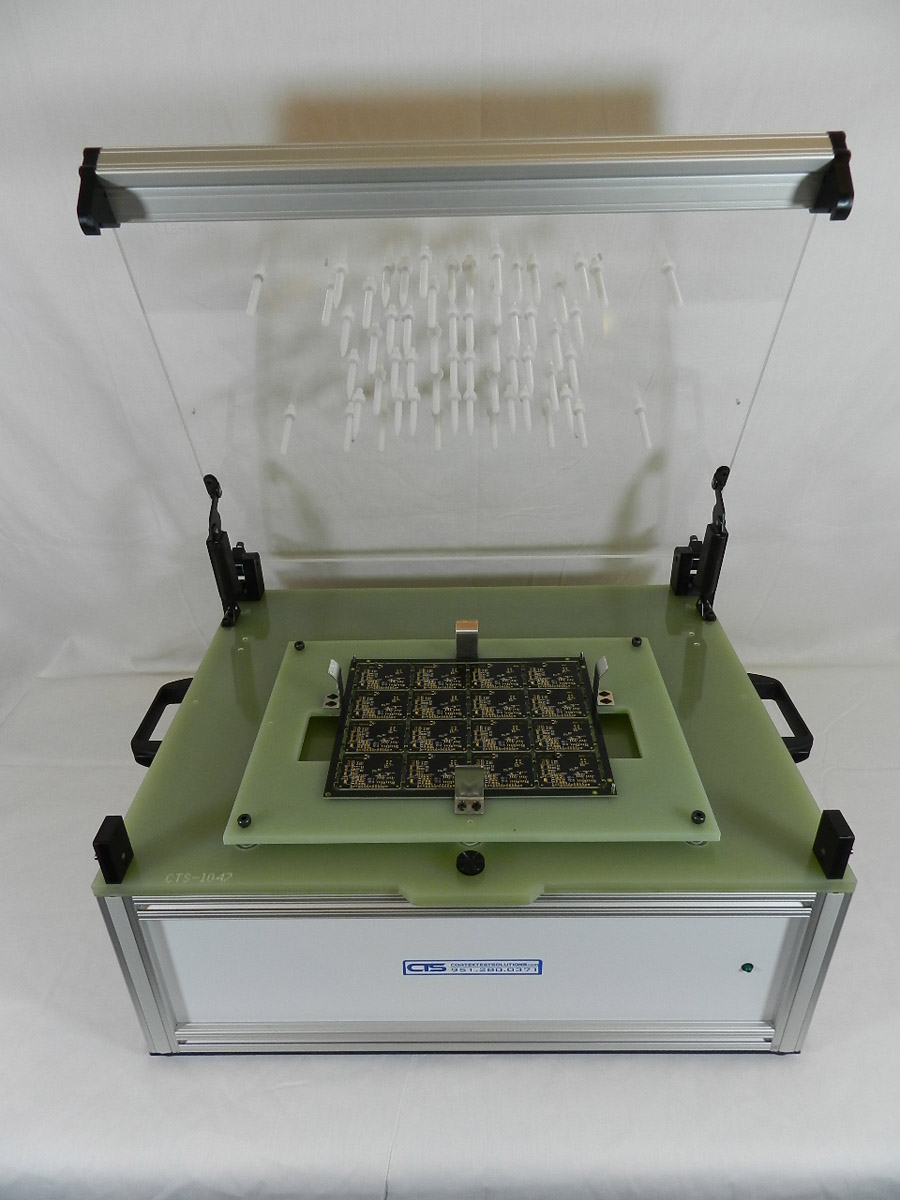

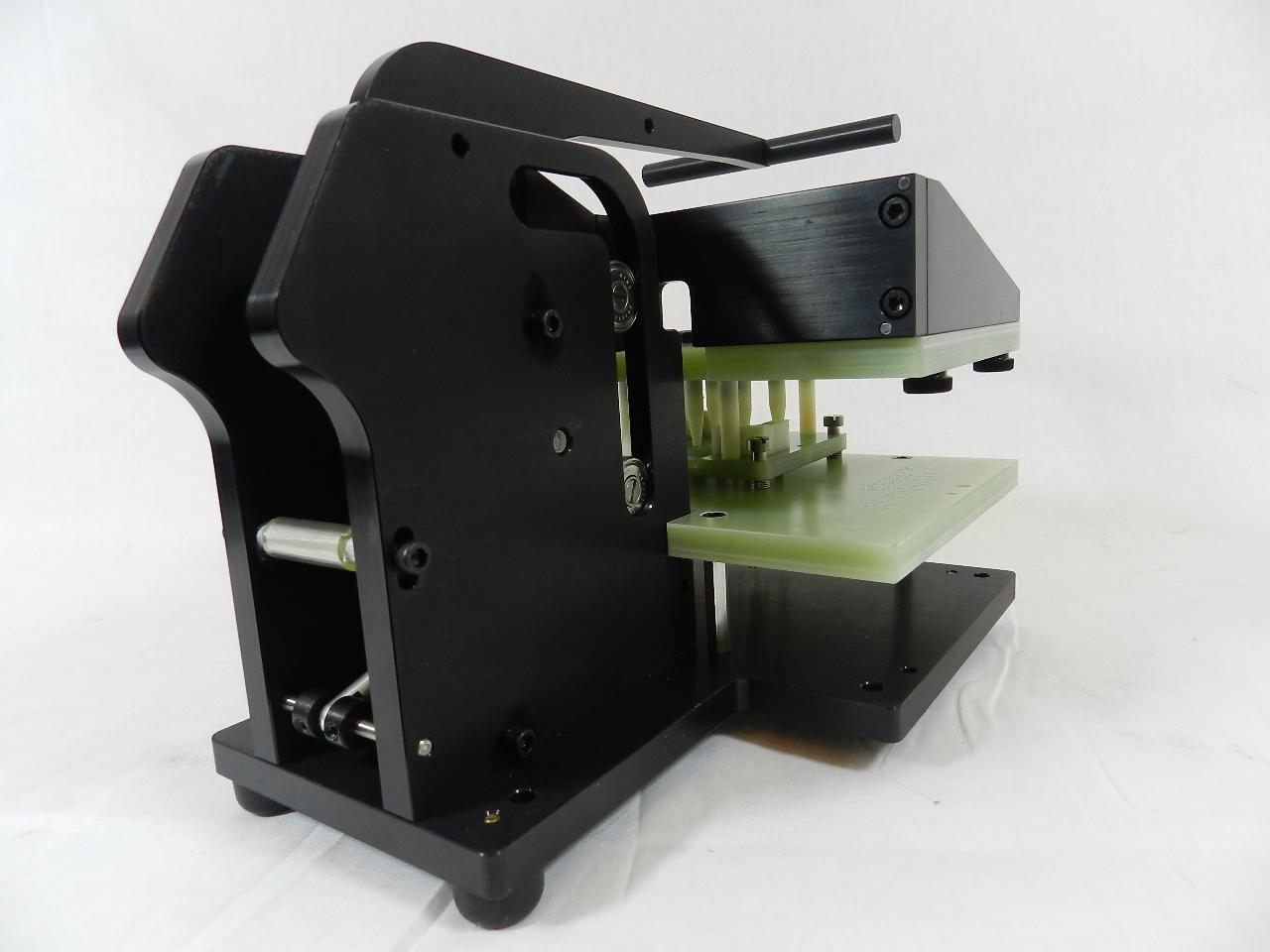

About Mechanical Press Fixture Kits

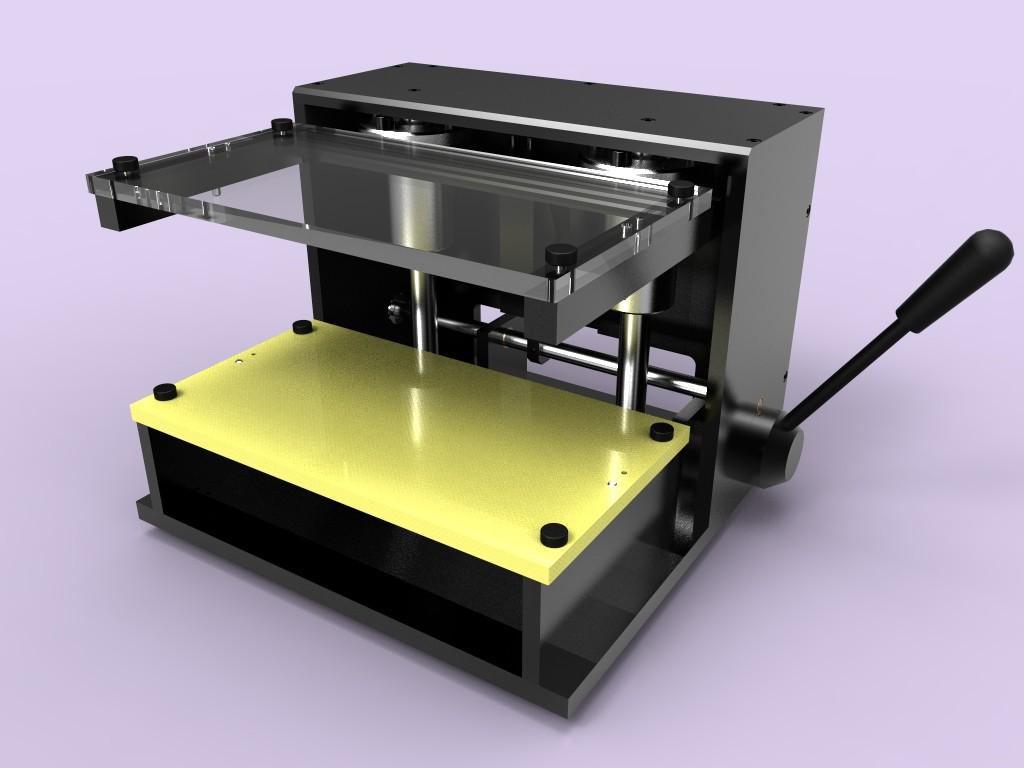

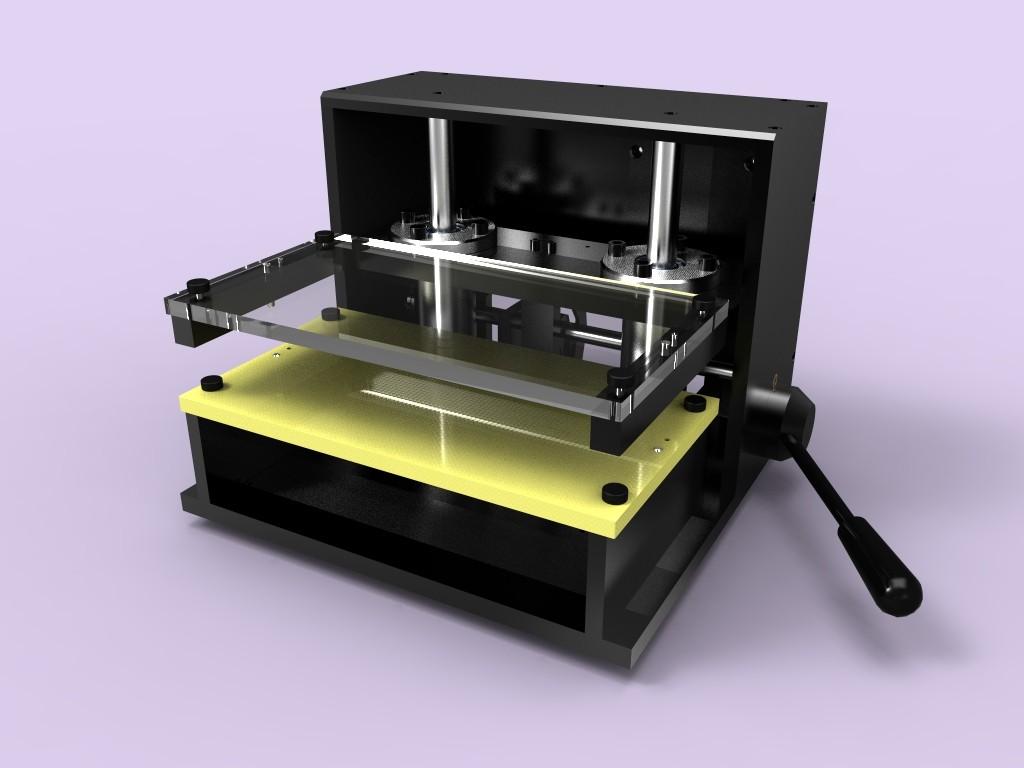

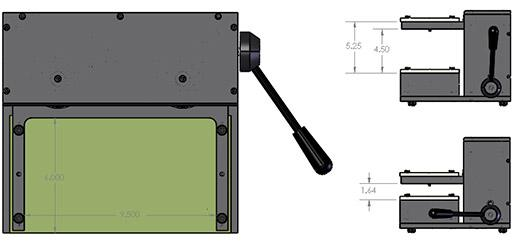

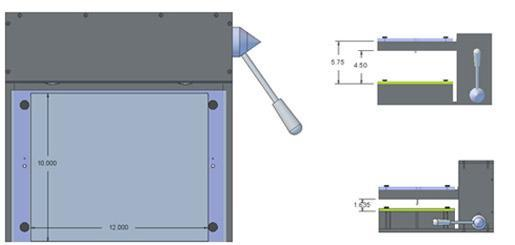

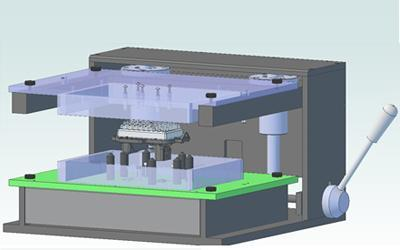

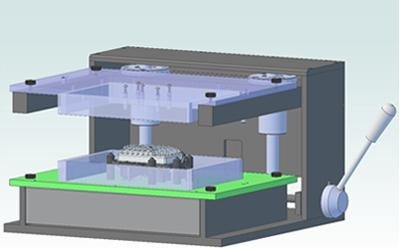

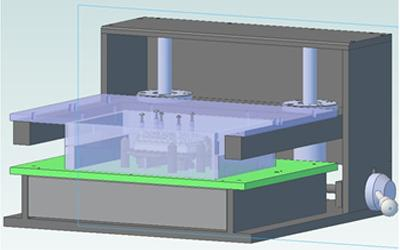

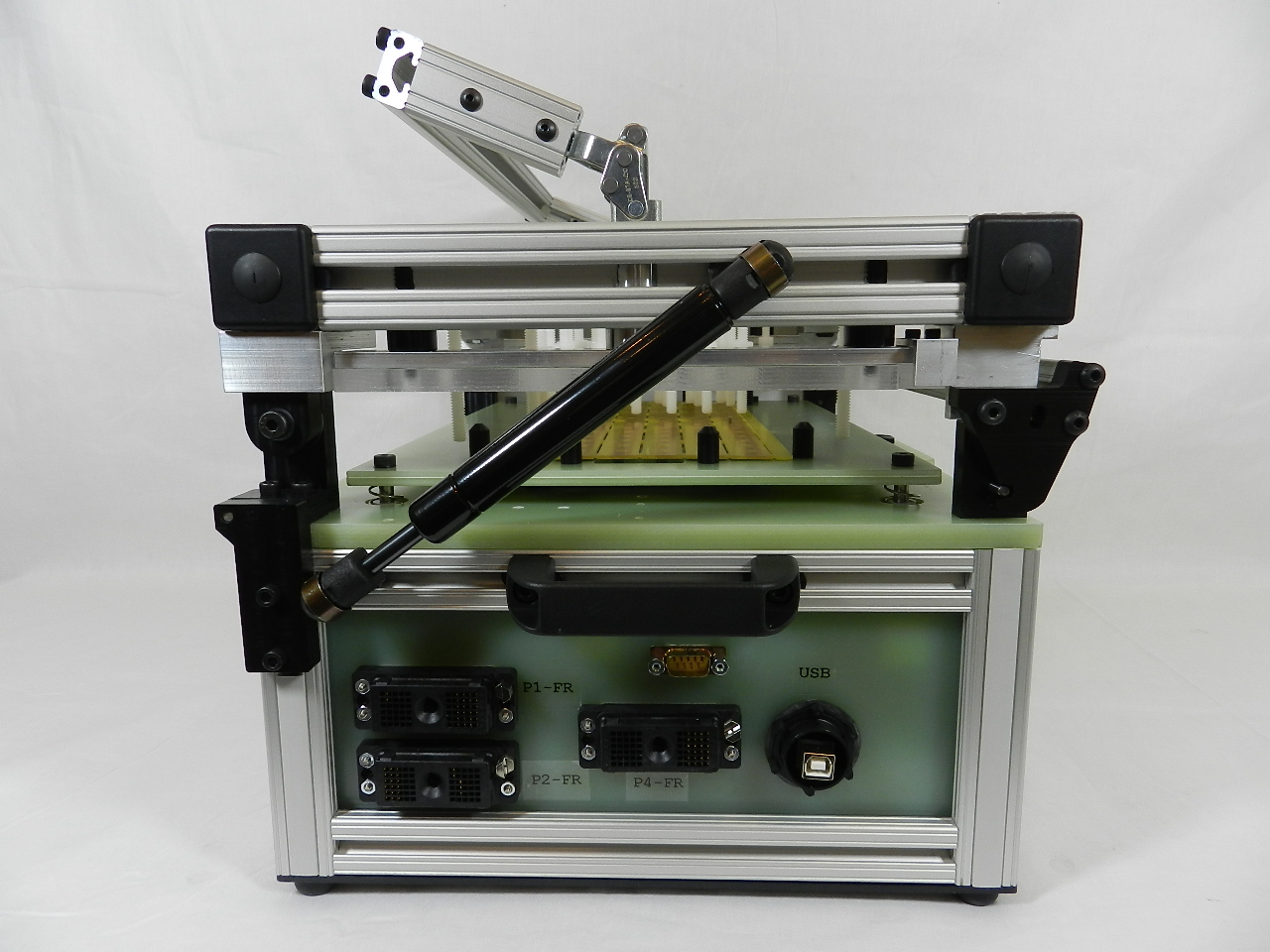

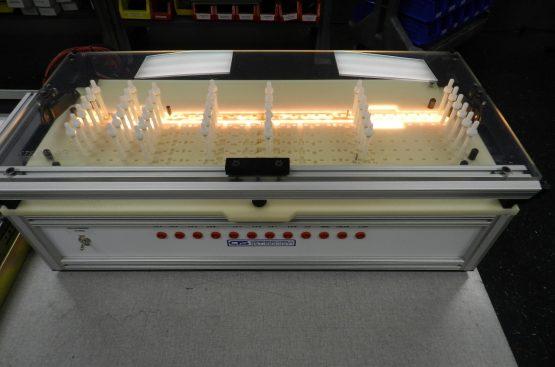

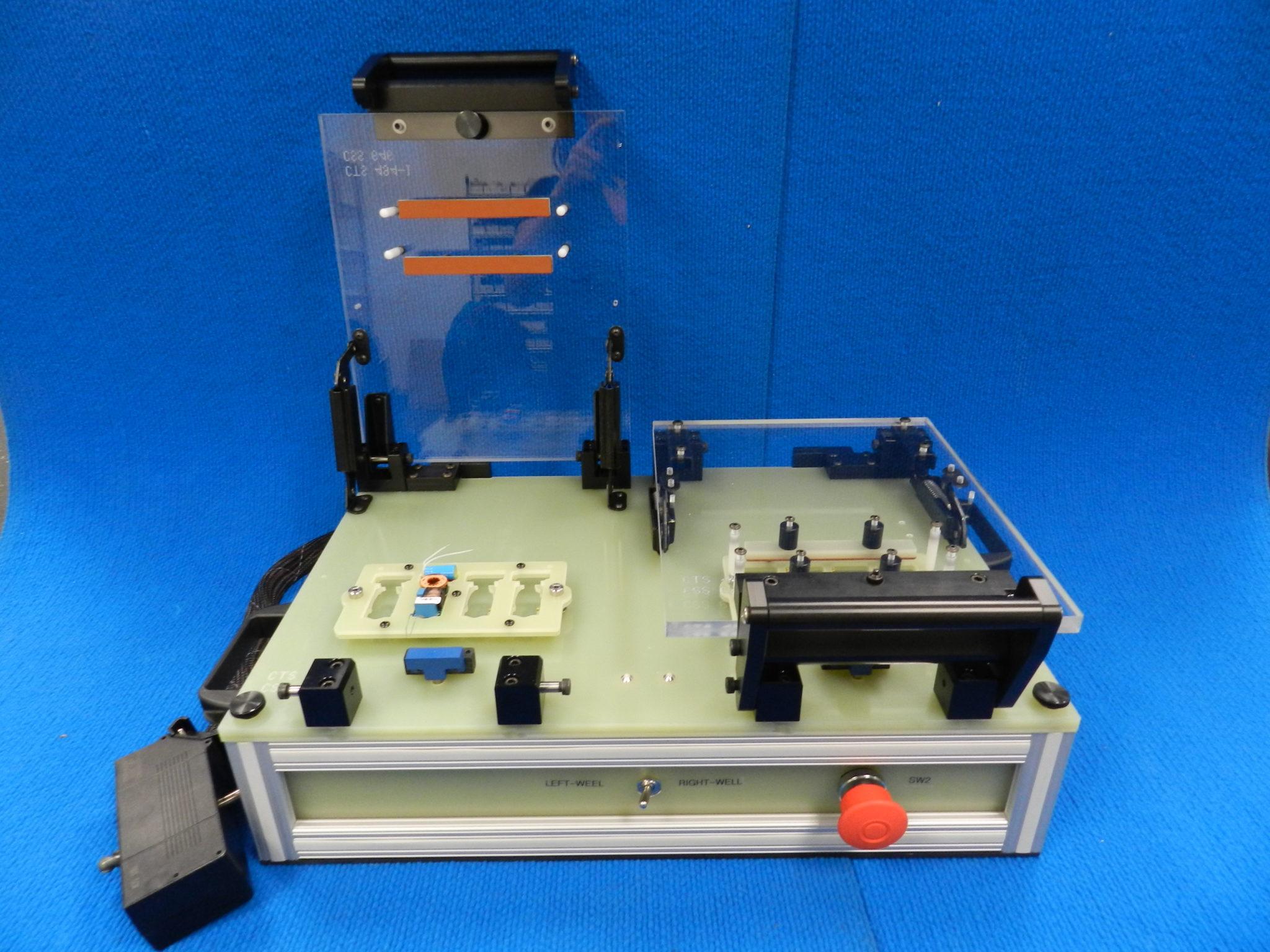

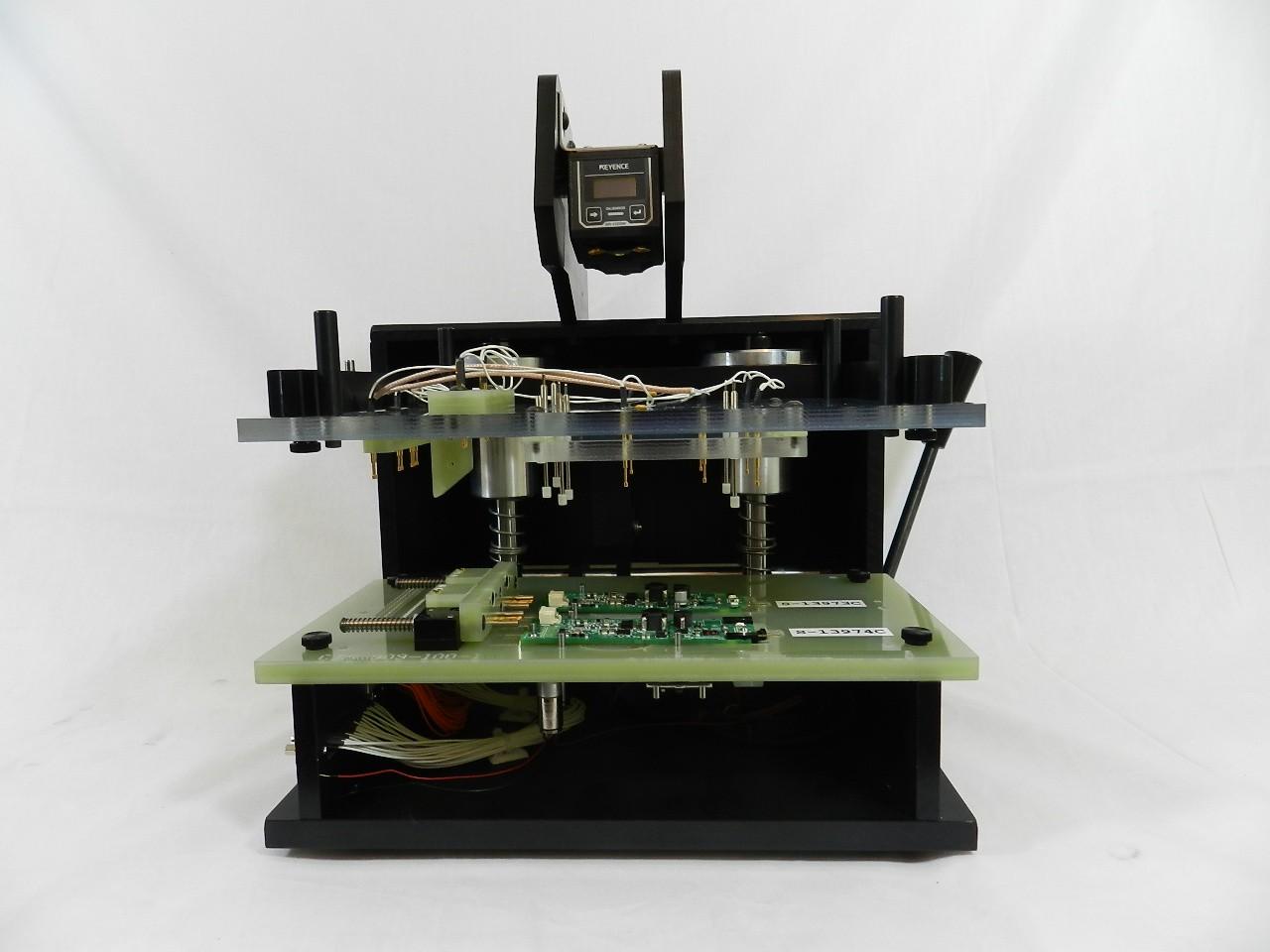

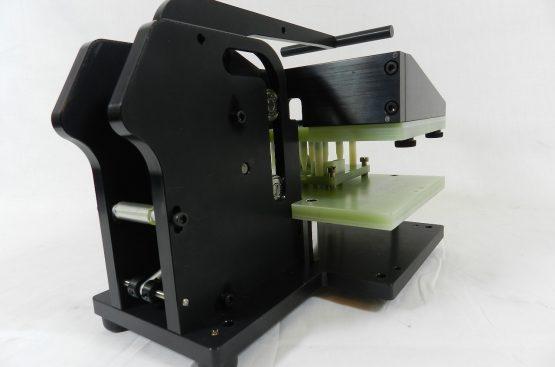

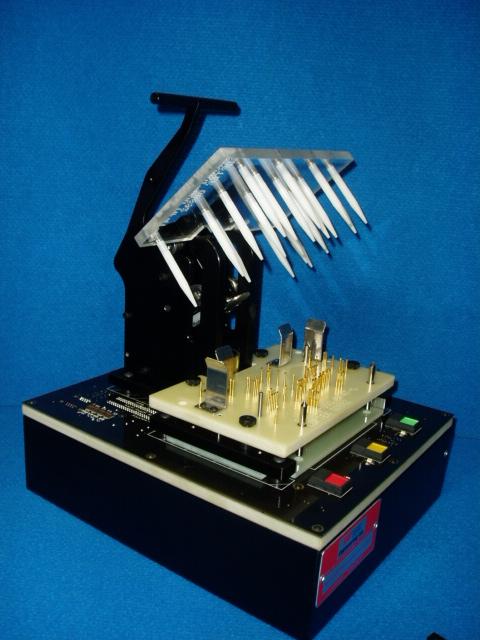

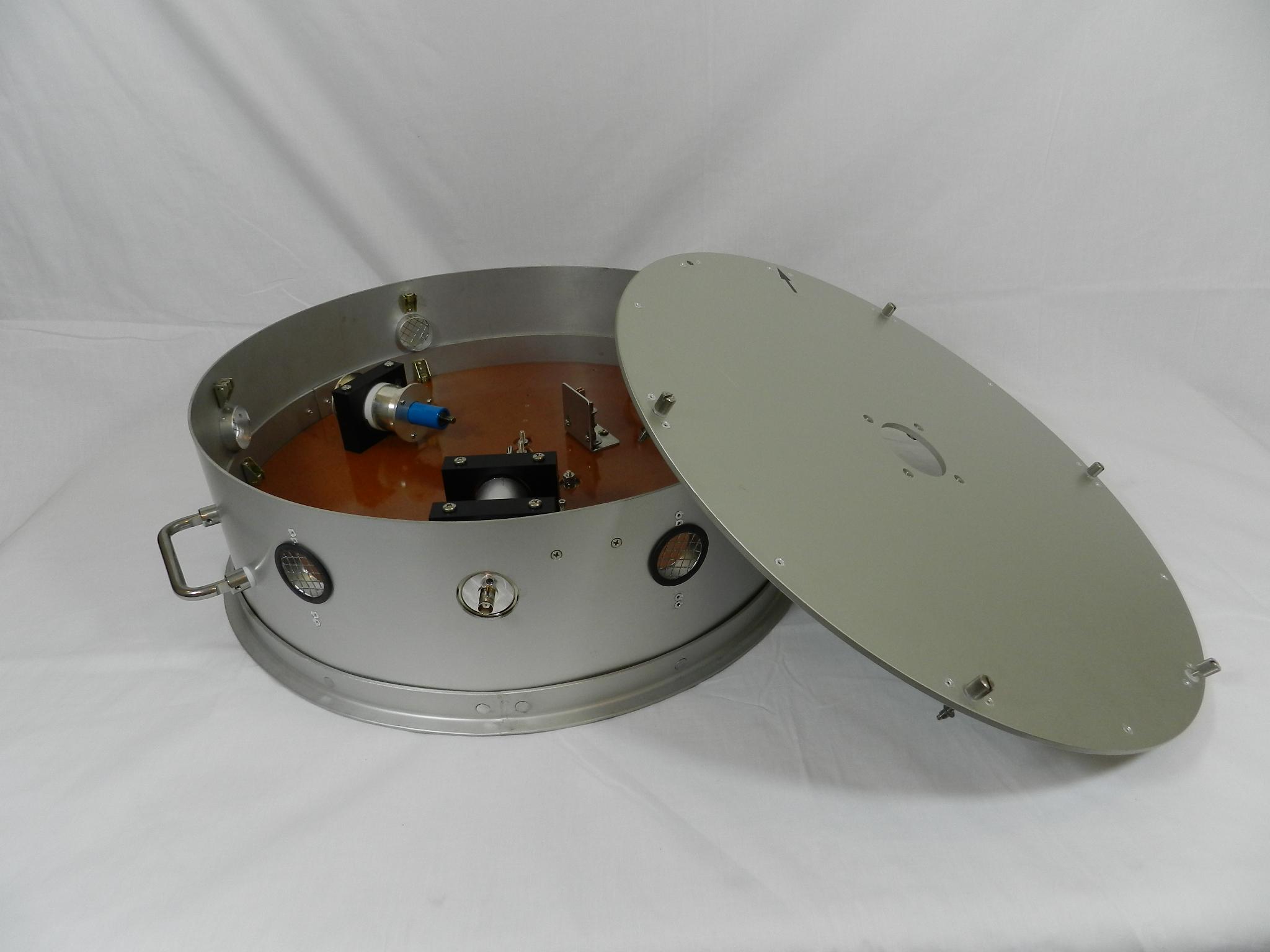

The mechanical press is a lever actuated vertical clamping press.

The mechanical press is a lever actuated vertical clamping press.

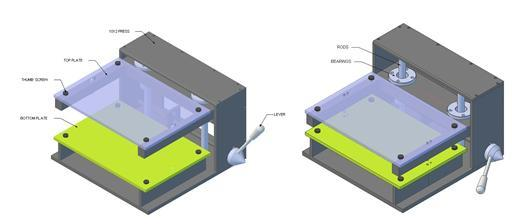

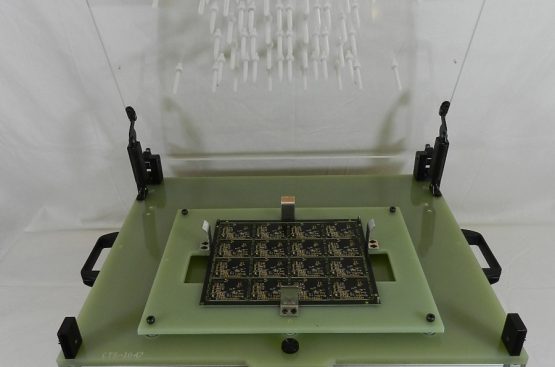

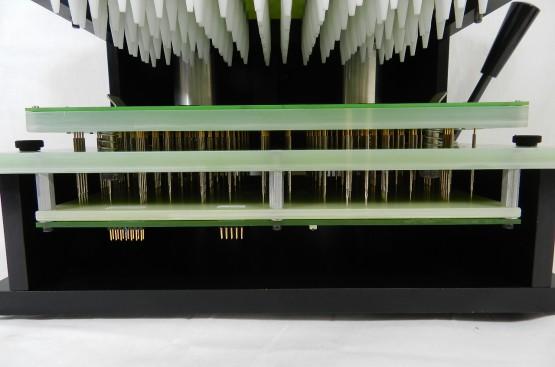

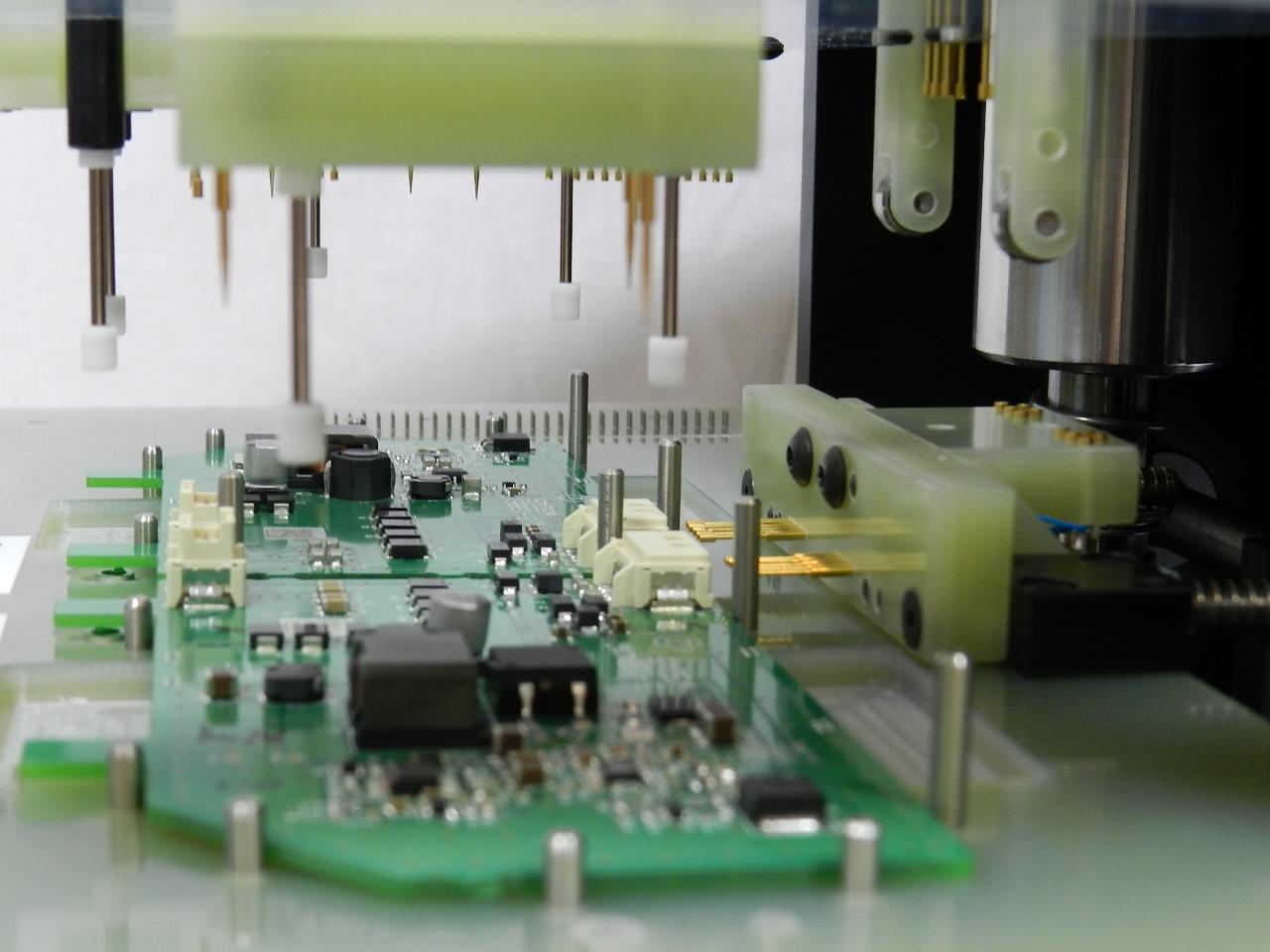

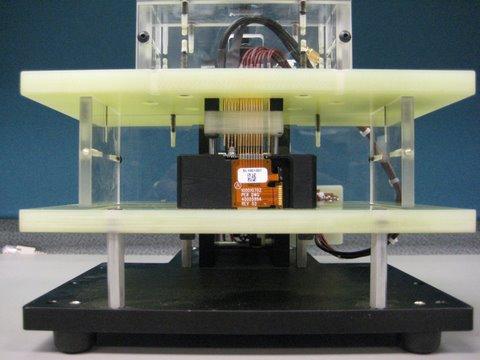

When the lever is moved the top plate is lowered through a geared toggle clamp mechanism that multiplies the force being exerted by the operator so that large forces can be applied by the clamping mechanism without operator fatigue. The upper mechanism travels on precision rods and bearings that insure precise repeatability with each actuation and a long service life.

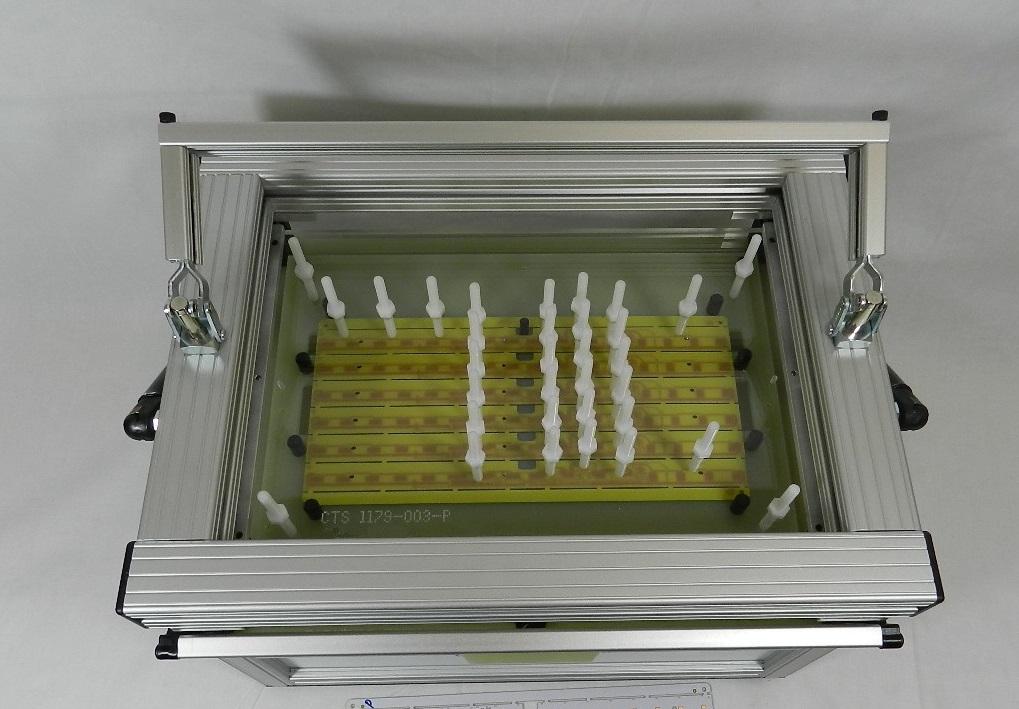

Fixtures can be removed from the press without tools by unscrewing the four thumb screws that hold down the top plate and the four thumb screws that hold the lower plate.