Description

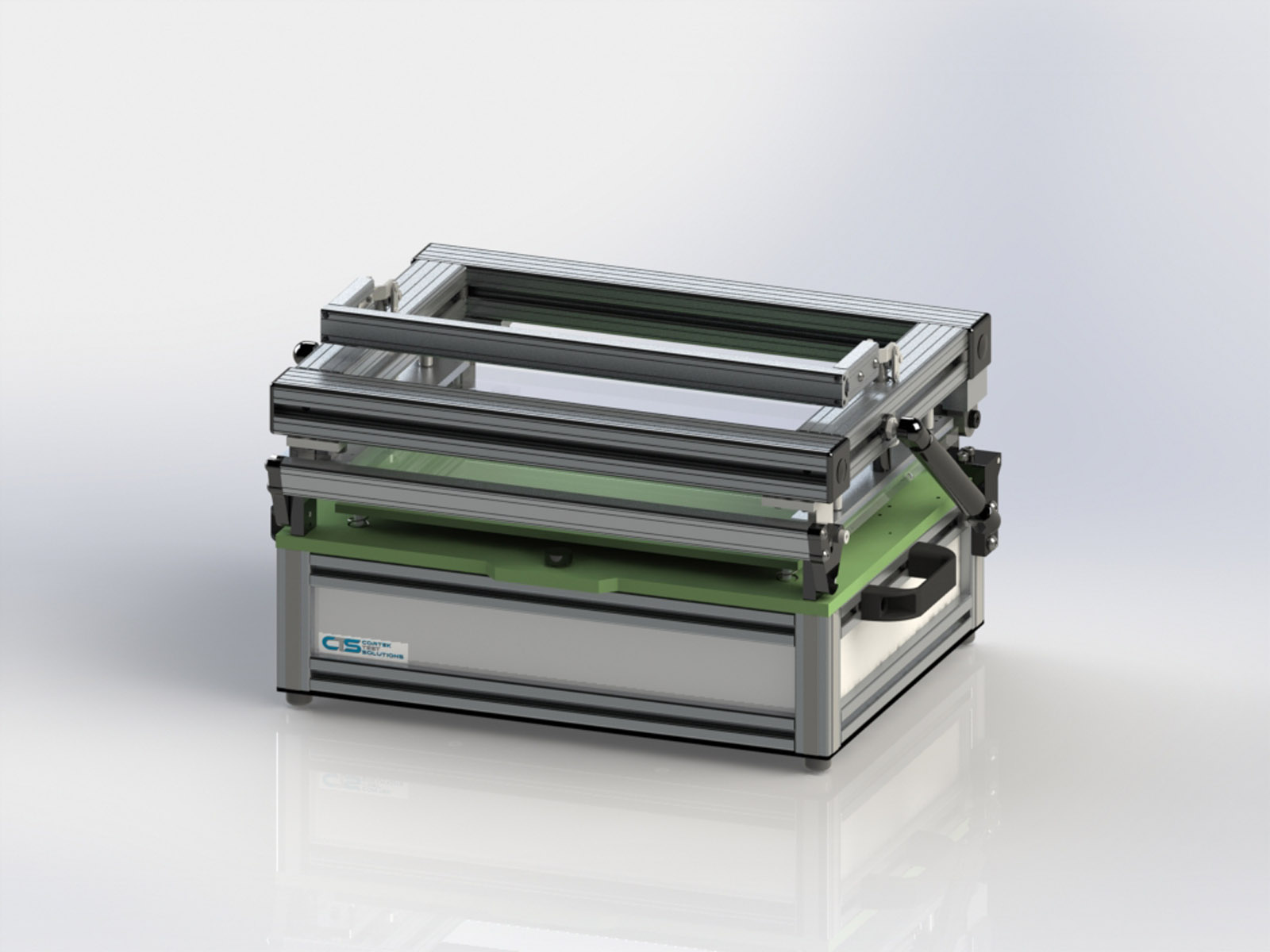

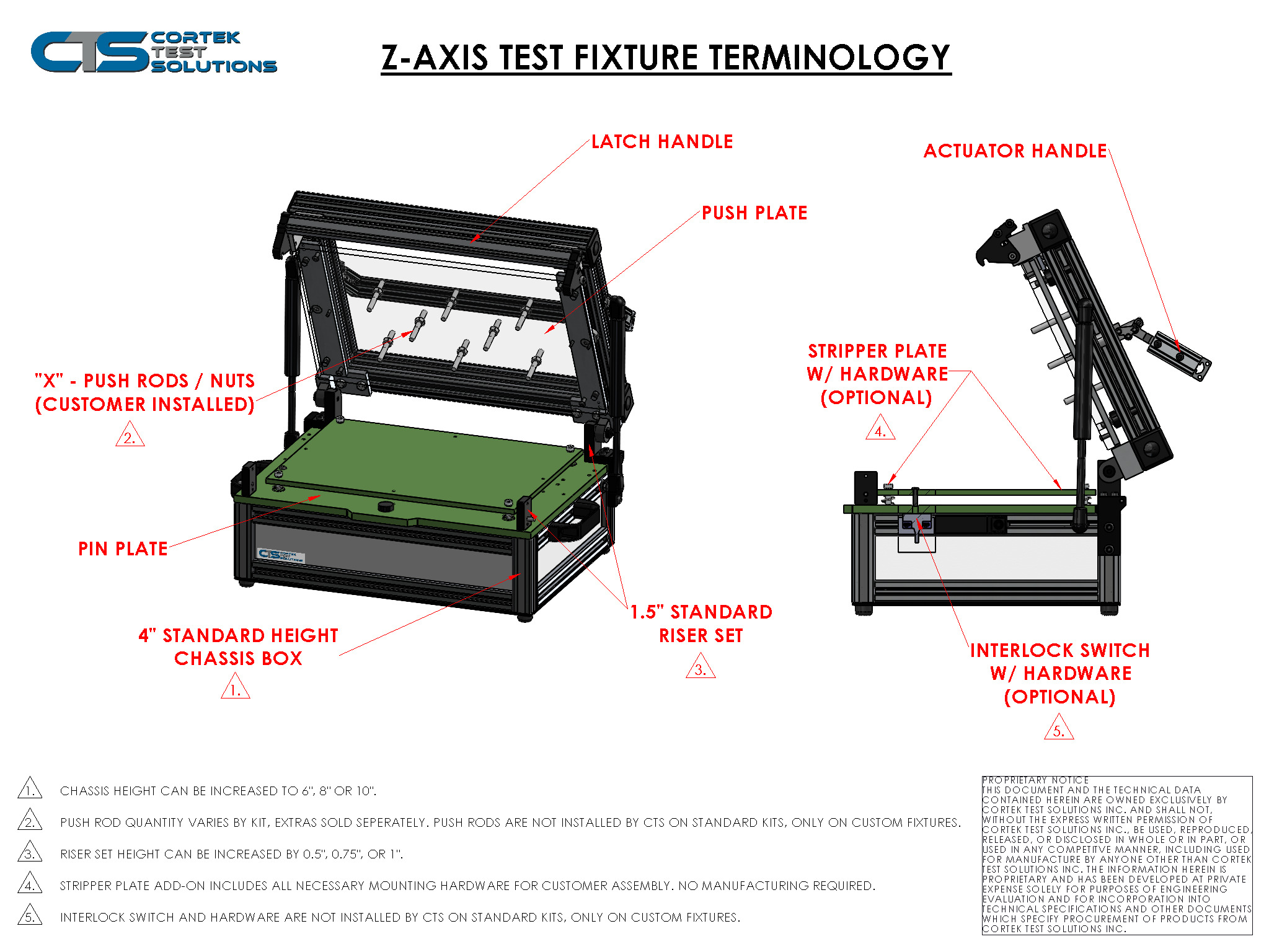

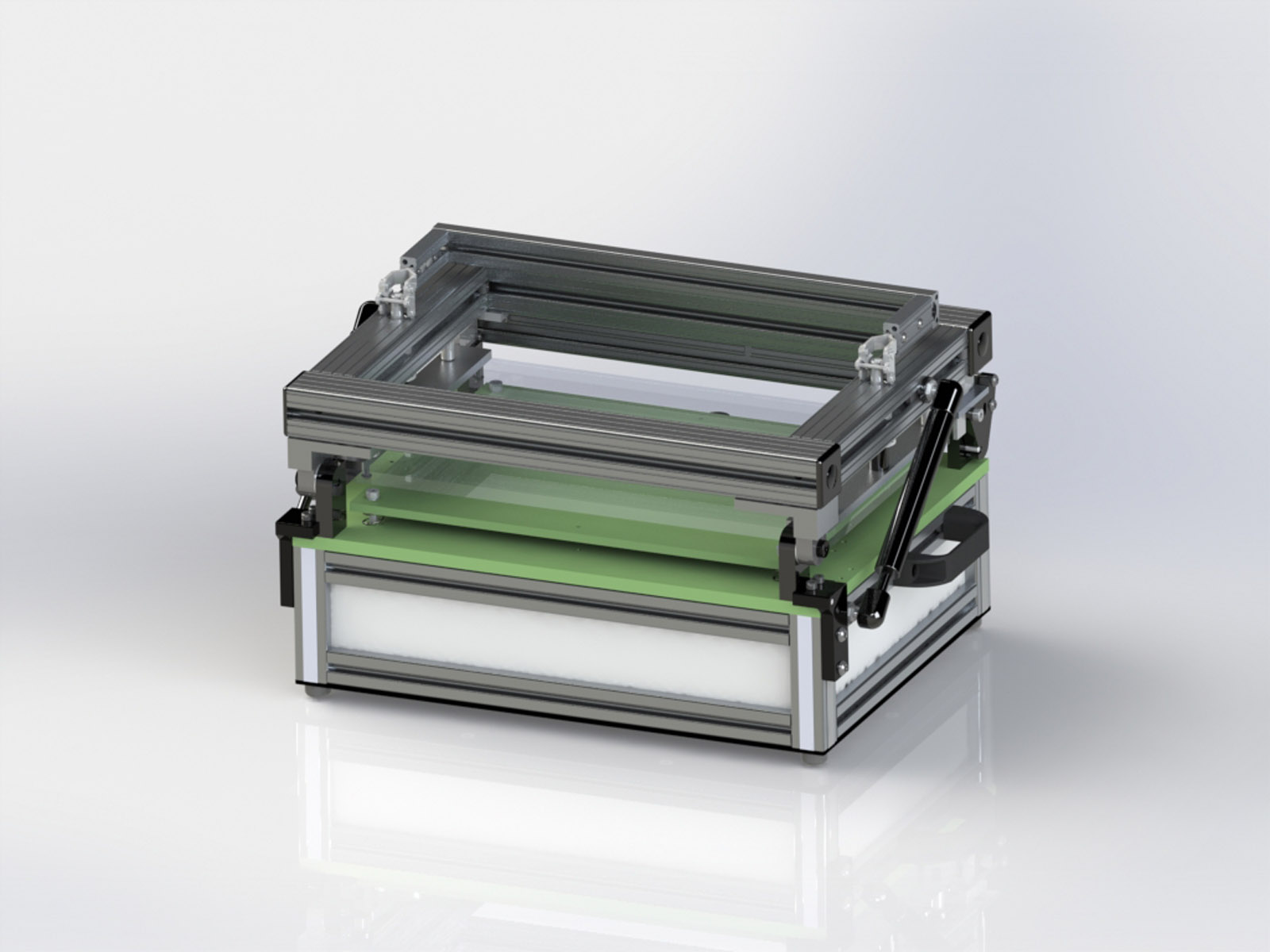

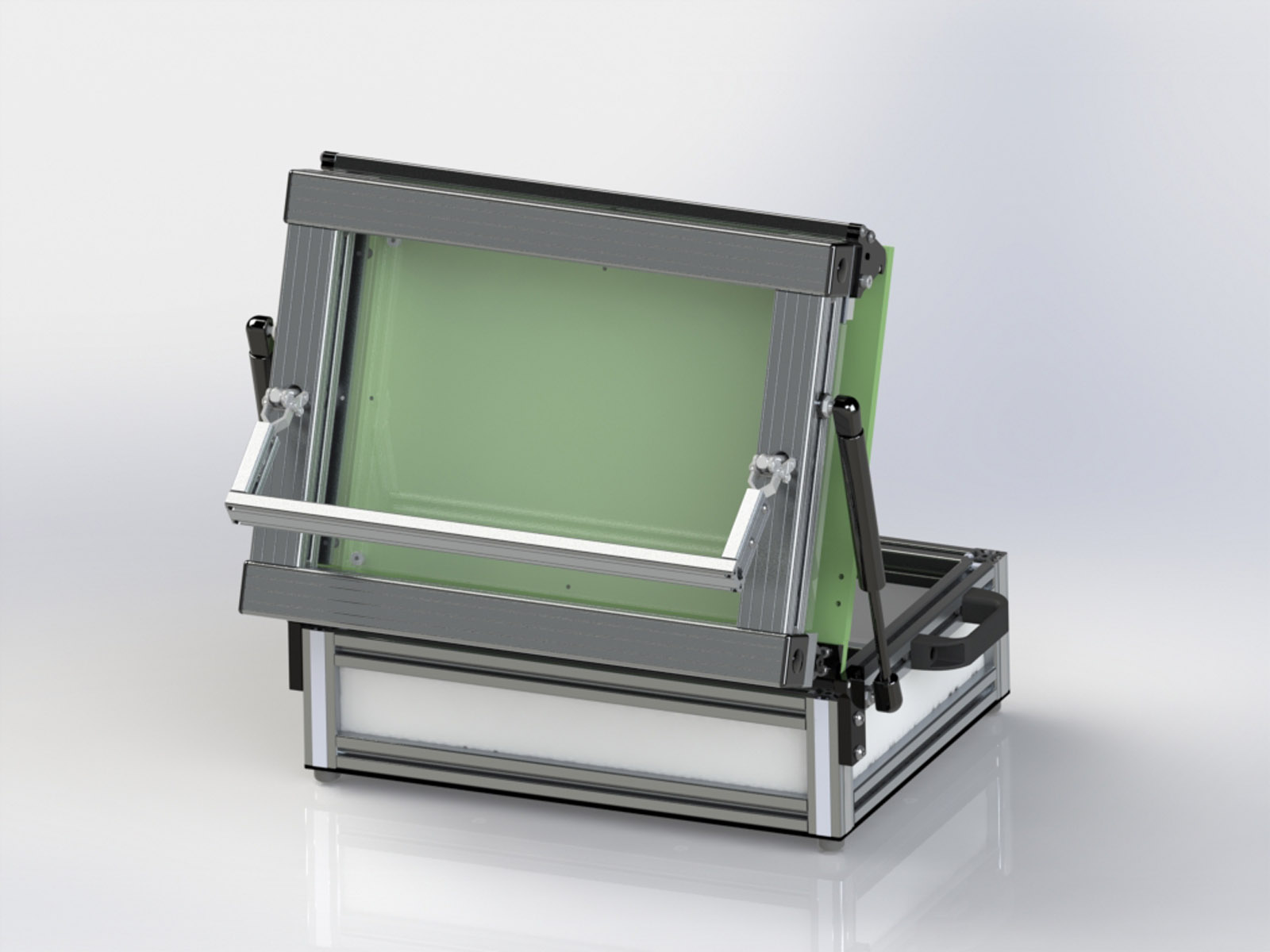

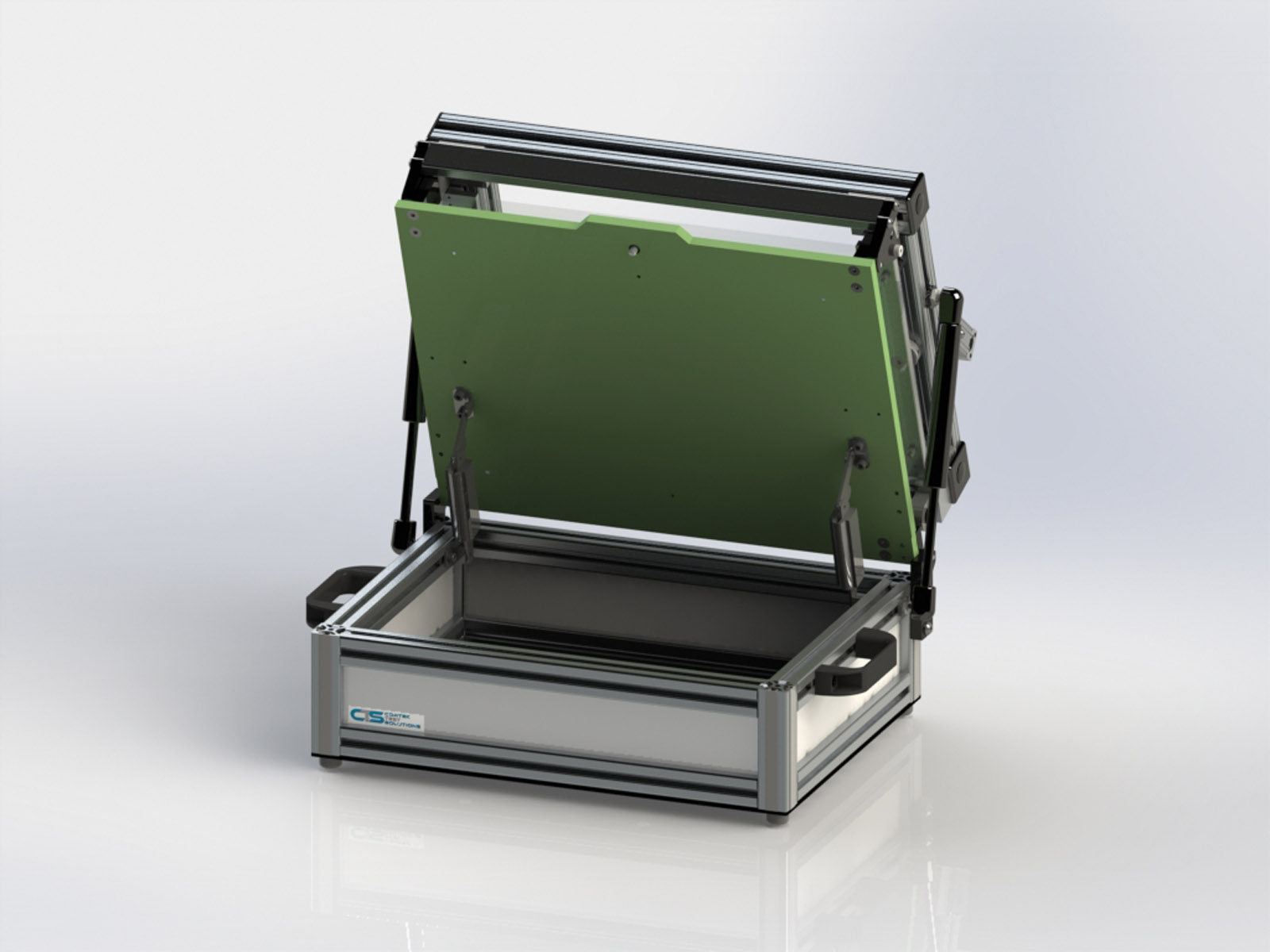

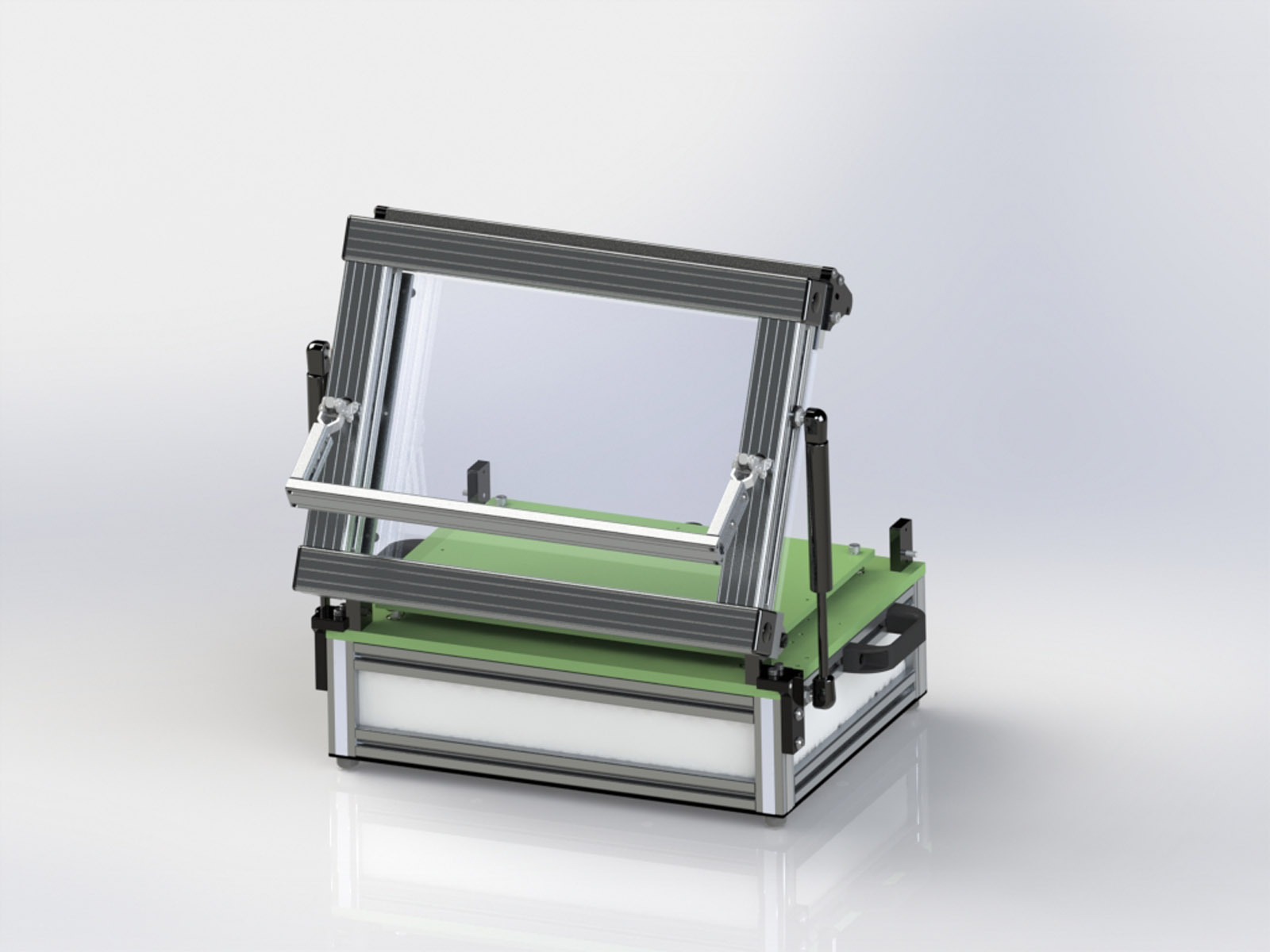

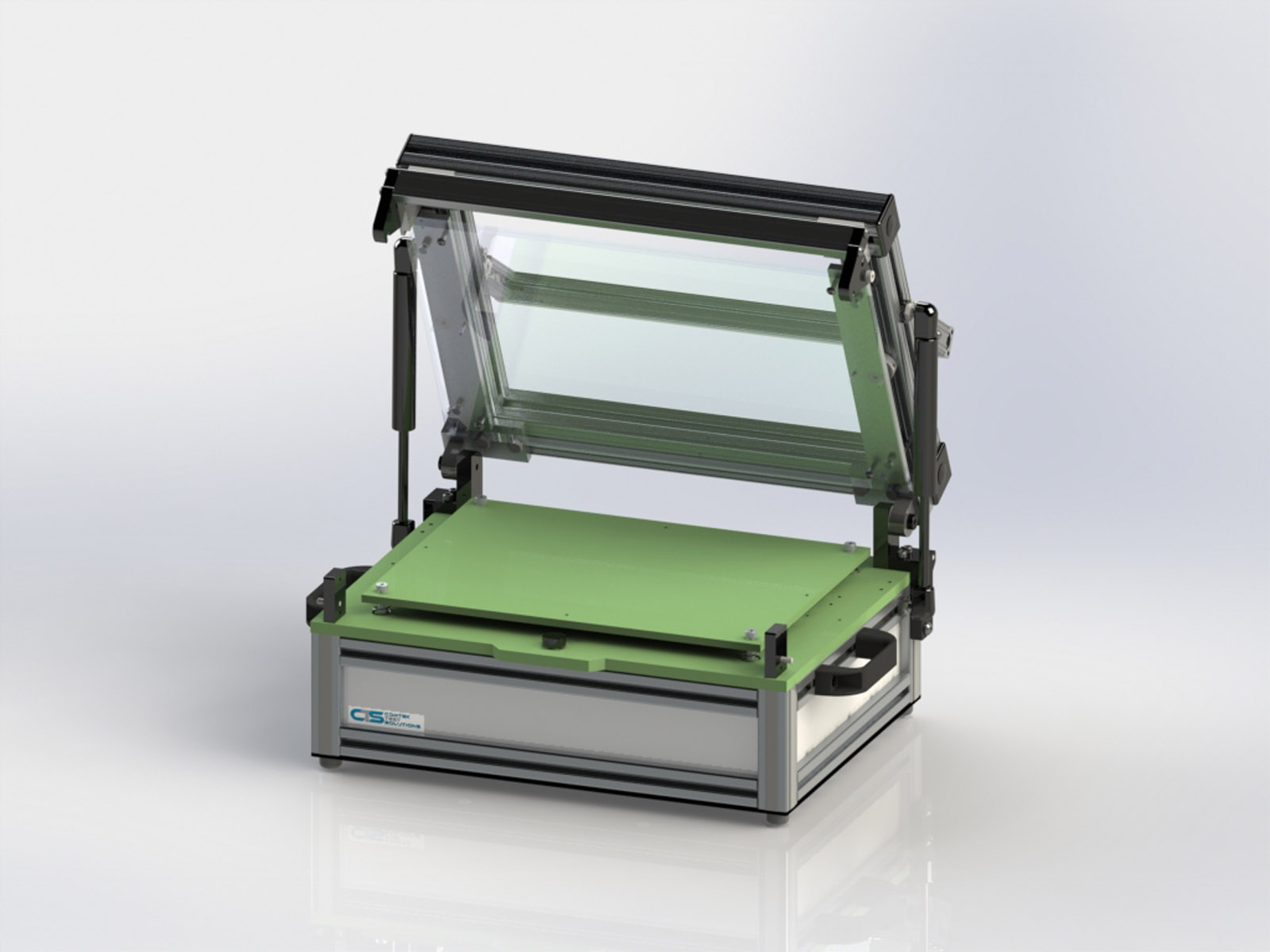

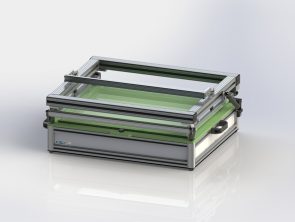

Introducing Cortek’s Z-axis test fixture kits, an affordable solution for testing printed circuit boards with precise linear engagement when a traditional “clamshell” style fixture is not suitable. These kits feature a Z-axis assembly that replaces the standard hinged top push plate found in our kits, and they are available in our standard sizes. The Z-axis assembly can also be purchased separately as an individual assembly, allowing for field upgrades. Just like our standard mechanical fixture kits, these units are fully customizable to meet any specific size requirements. Experience accurate testing and reliable performance with Cortek’s Z-axis test fixture kits. Upgrade your testing capabilities today!

Cortek provides Z-axis test fixture kits that are a cost-effective alternative for testing printed circuit boards, ensuring accurate linear engagement when a traditional “clamshell” style test fixture doesn’t fit the need. The Z-Axis component can be used to substitute the conventional hinged top push plate included in our kits and is available in our standard dimensions. If required, this assembly can be acquired separately for an upgrade in the field. These units can be tailored for any specialized size specifications, in line with our usual mechanical fixture kits.